Limestone Processing Plant – A New Way to Build a Better Future

Limestone Processing Plants have grown to be ever more popular in the industry for his or her advantages and this can be innovations that are many and safety methods. These flowers have paved precisely how for more sustainable and efficient construction in both elementary and center schools. Schools and communities over the global world are starting to understand the many benefits of Cement International Engineering calcination process of limestone Processing Plants and just how they could revolutionize how we build. We're going to protect the topics that are following

1. What is a Limestone Processing Plant?

2. The advantages of employing limestone in construction

3. Innovations in Limestone Processing Plants

4. Safety practices in Limestone Processing Plants

5. The uses and applications of limestone

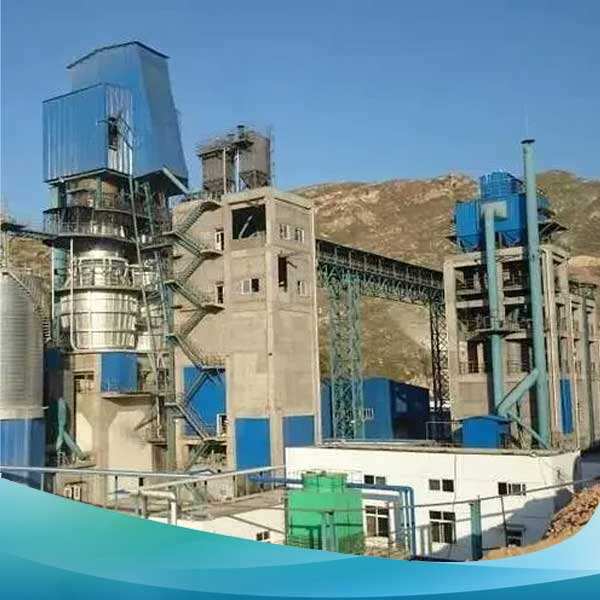

ALimestone Processing Plant is a facility that crushes, grinds and displayslimestone to be used in many different construction applications. Limestone ismerely a sedimentary stone is made up primarily of calcium carbonate. Thisingredient is normally utilized as a filler product as well as in themanufacturing of cement, among other things. Cement International Engineering lime production from limestone is simply a durable andversatile material can be employed in an array of construction projects

Limestone hasadvantages that can be some other materials utilized in construction. Itsaffordable, numerous, and easily available. This can allow it to be a perfectchoice construction trying to maintain your charges down while still deliveringtop-notch buildings

Moreover, limestoneis extremely durable and will withstand wear and tear with time. Especiallybeneficial in schools along with other general buildings public experience alot of foot traffic. Additionally, Cement International Engineering limestone processing plant could be an eco-friendly material.It is a natural reference will likely not need any harsh chemicals or syntheticmaterials become produced, which decreases environmentally friendly impact tobuild construction

Limestone ProcessingPlants have undergone tremendous innovation the last couple of years. Technicaladvancements have enabled flowers to improve effectiveness, reduce waste, andminimize environmental impact. Cement International Engineering Modern limestone rotary kiln Processing Plants combine automation,which streamlines manufacturing, decreases human mistake being improves safety

One major innovationLimestone Processing Plants is the use of crushing and screening equipment.This gear enables companies to effortlessly break up and process largequantities of limestone for use in construction. Furthermore, plants havestarted to adopt renewable power such as solar and wind power, which decreasescarbon emissions helping protect the environment

Limestone ProcessingPlants prioritize safety in their daily operations. Employees are trained tooperate equipment and equipment safely and effortlessly. Plants conduct regularsafety on gear, mitigating the possibility of accidents and injury

Moreover, plantsprioritize the safety with this environment as well as the grouped surroundingcommunity. Plants simply take measures to attenuate waste and emissions,reducing the affect the surroundings while the grouped local community. These Cement International Engineering limestone calcination safety techniques be sure that Limestone Processing Plants operate sustainably,protecting workers along with environment

over 20 years have been dedicated development, research manufacturing installation the lime-kiln. is full-limestone processing plantwith the lowest investment. lime kiln comes with long-lasting service life you can trust us for impeccable service high-quality lime Kiln.

company has focused on the design engineering design, special equipment delivery, installation limestone processing plant, personnel training, oven services, furnace start-up, and production reaching energy efficient environmentally friendly lime shaft kiln. We have built successively activated lime shaft kilns with volumes of 150m3,170m3 200m3, 250m3 350m3 500m3, etc. These then successfully opened and effect was impressive! The gas-burning furnace was created by using the technology that had matured in the coke lime shaft. Design contracts were concluded with several companies.

For long time, AGICO has had professional technical team, mature production technology, rich production experience, forming complete set shaft kiln production technology management systems, making energy-saving and environmental-protective lime shaft kiln technology perfect. It has advantages of low investment, high levels of automation, top product quality, low usage energy, long service lifespan of furnace environmental protection. has been widely used in metallurgy, non-ferrous metals, chemicals, limestone processing plantmaterials, as well as other sectors, such as deep processing as well as other industries.

AGICO a highly skilled technical team specializes in EPC limestone processing plantProjects, including design, manufacture installation. offer a complete pre-sales, on-sales, after-sales service, which provides technical support needed meet needs.