Energy-saving Double Shaft Lime Kiln For Lime Manufacturing

| Capacity: | 300-800 t/d (adjustable) |

| Limestone Particle Size: | 30-60mm; 40-80mm |

| Fuel: | gas, oil, pulverized coal, etc. |

| Activity Degree: | 360-400 ml |

| Features: | Chinese Maerz kiln, large feed particle size, high price, most energy-saving, various fuels available, and highest activity value. |

Overview

Inquiry

Related Products

Description:

The Double Shaft Lime Kiln stands as a pinnacle of innovation in lime production, embodying cutting-edge technology and efficiency. This robust kiln is meticulously engineered to transform limestone into high-quality lime with unparalleled precision. Its dual shaft design ensures optimal thermal processing, fostering uniformity in product quality.

Crafted from durable materials, the kiln guarantees longevity and resilience, withstanding the rigors of continuous operation. The meticulous attention to detail extends to its dimensions and parameters, striking a delicate balance between compactness and high-capacity lime production. Its versatile nature accommodates various limestone types, making it a flexible solution for diverse industrial applications.

Structural Features:

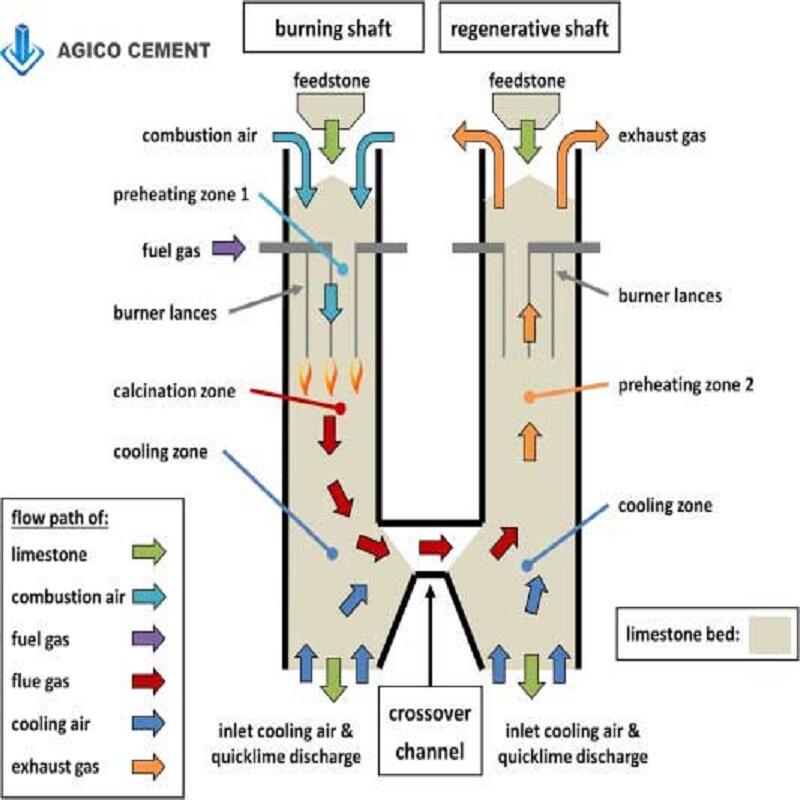

Combustion in a Double Shaft Lime Kiln always occurs when the burning air and fuel flow downward. In each kiln, the limestone also moves downward, a process called "co-flow," which is the first of two characteristics of the kiln. And a very hot flame flows in contact with limestone and cooler gas to complete the calcining process. The limestone raw material at the initial end of the combustion zone cannot be over-burned, and the heat exchange rate may be high. Near the end of the cooler burning zone, calcination of limestone is completed and uniform light calcination conditions are obtained.

The second feature of the Double Shaft Lime Kiln is the "regenerative" heat storage process, which takes place in the preheating zone. In this area, the limestone becomes a huge heat exchanger, absorbing the heat from the exhaust gas and reducing the gas to very low temperatures. In the next cycle, some of the heat is released into the inhaled combustion air, bringing the combustion air to a burning temperature before it comes into contact with the fuel. This process is very efficient, and the heat of the exhaust gas is fully utilized, which is largely the reason for the extremely high thermal efficiency of the Double Shaft Lime Kiln.

Competitive Advantage:

lHigh efficiency; The process of a double lime kiln can make full use of the heat energy of fuel and increase the output of lime. Compared with traditional lime kilns, the lime production of double shaft lime kilns can be increased by 20%Thirty percent.

lExcellent quality: in the process of double lime kiln. Limestone is calcined at high temperatures, which can better decompose and produce lime. And remove impurities from the limestone, so double bore the calcareous halos produced by lime kilns are better. More suitable for industrial and construction applications.

lEnergy saving: In the double shaft lime kiln process, the limestone in the preheating chamber carries out indirect heat exchange with the high-temperature flue gas in the combustion chamber. It heats the limestone, reducing fuel consumption. Phase Compared with the traditional lime kiln, the double lime kiln can save 20% to 30% of fuel.

lEnvironmentally friendly: Double lime kiln process. The high-temperature flue gas in the combustion chamber can take away the impurities in the limestone and reduce the pollution to the environment. At the same time, the double shaft lime kiln is still OK. It is used in combination with environmental protection facilities such as dust removal equipment to reduce emissions in the lime production process.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ