Parallel Flow Regenerative Twin Shaft Lime Kiln

| Capacity: | 300-800 t/d (adjustable) |

| Limestone Particle Size: | 30-60mm; 40-80mm |

| Fuel: | gas, oil, pulverized coal, etc. |

| Activity Degree: | 360-400 ml |

| Features: | Chinese Maerz kiln, large feed particle size, high price, most energy-saving, various fuels available, and highest activity value. |

Overview

Inquiry

Related Products

Description:

The Twin-Drive Lime Kiln represents a pinnacle of lime production innovation, incorporating state-of-the-art technology and efficiency. This robust kiln is intricately designed to convert limestone into top-tier lime with unmatched precision. Its dual-shaft configuration ensures optimal thermal processing, promoting consistency in product quality.

Constructed from resilient materials, the kiln assures longevity and durability, enduring the demands of continuous operation. Precision in dimensions and parameters is a focal point, achieving a delicate equilibrium between compactness and high-capacity lime production. Its versatility caters to different limestone types, establishing it as a flexible solution for a range of industrial applications.

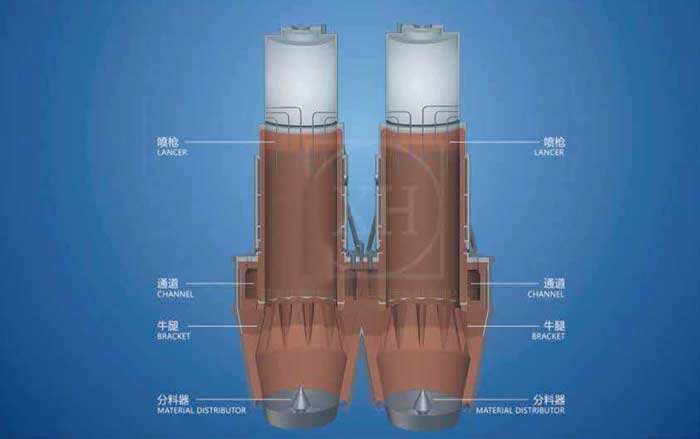

Structural Features:

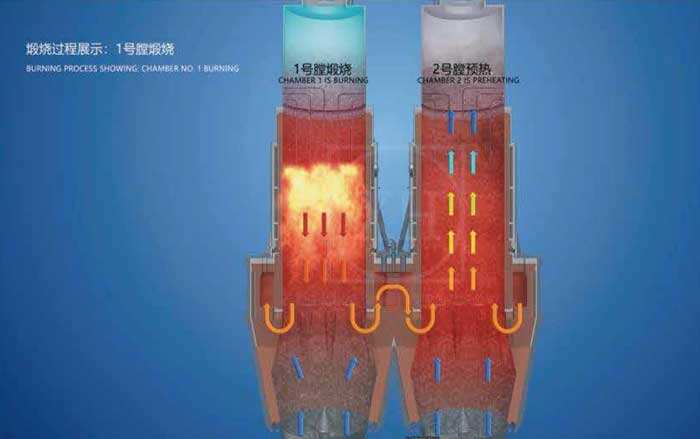

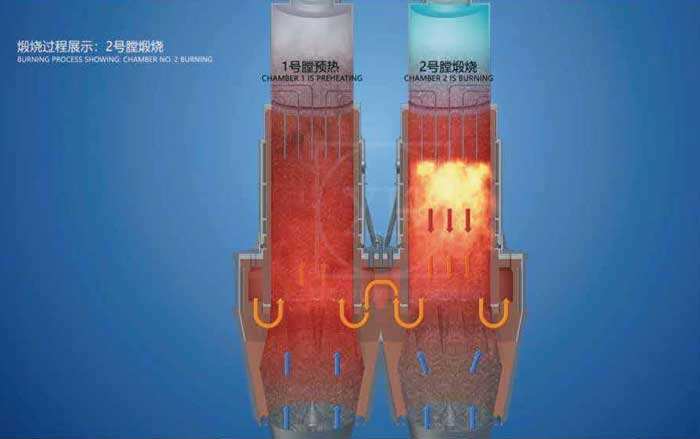

In a Double Shaft Lime Kiln, combustion consistently occurs as burning air and fuel move downward. The limestone in each kiln undergoes a simultaneous downward movement, known as "co-flow," marking the first distinctive characteristic of the kiln. A highly intense flame interacts with limestone and cooler gas, facilitating the calcining process. At the initial end of the combustion zone, over-burning of the limestone raw material is prevented, ensuring a potentially high heat exchange rate. Towards the end of the cooler burning zone, limestone calcination is completed, achieving uniform and lightly calcined conditions.

The second notable feature of the Double Shaft Lime Kiln is the "regenerative" heat storage process in the preheating zone. Here, limestone functions as a substantial heat exchanger, absorbing heat from exhaust gas and lowering the gas temperature significantly. In the subsequent cycle, some of this stored heat is released to preheat the incoming combustion air, elevating it to burning temperature before reaching the fuel. This process is exceptionally efficient, fully harnessing the heat from exhaust gas, contributing significantly to the remarkable thermal efficiency of the Double Shaft Lime Kiln.

Competitive Advantage:

lEnhanced Efficiency: The double lime kiln process maximizes fuel heat energy utilization, leading to a notable increase in lime output. Compared to conventional lime kilns, double shaft lime kilns exhibit a 20% to 30% boost in lime production.

lSuperior Quality: Within the double lime kiln process, high-temperature calcination of limestone ensures optimal decomposition and lime production, effectively eliminating impurities. The resultant lime is of superior quality, making it more suitable for industrial and construction applications.

lEnergy Conservation: In the double shaft lime kiln process, limestone undergoes indirect heat exchange with high-temperature flue gas in the preheating chamber, reducing fuel consumption. This energy-efficient approach enables the double lime kiln to save 20% to 30% of fuel compared to traditional lime kilns.

lEnvironmentally Responsible: The double lime kiln process utilizes high-temperature flue gas in the combustion chamber to remove impurities from limestone, minimizing environmental pollution. Additionally, when paired with environmental protection tools like dust removal equipment, the double shaft lime kiln further reduces emissions during lime production.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ