Lime Shaft Kiln Plant

| Capacity: | 80-1200 t/d |

| Selectable Fuel: | oil, natural gas, coal, etc. |

| Calcination Kiln: | rotary lime kiln, different types of vertical lime kiln |

Overview

Inquiry

Related Products

Description:

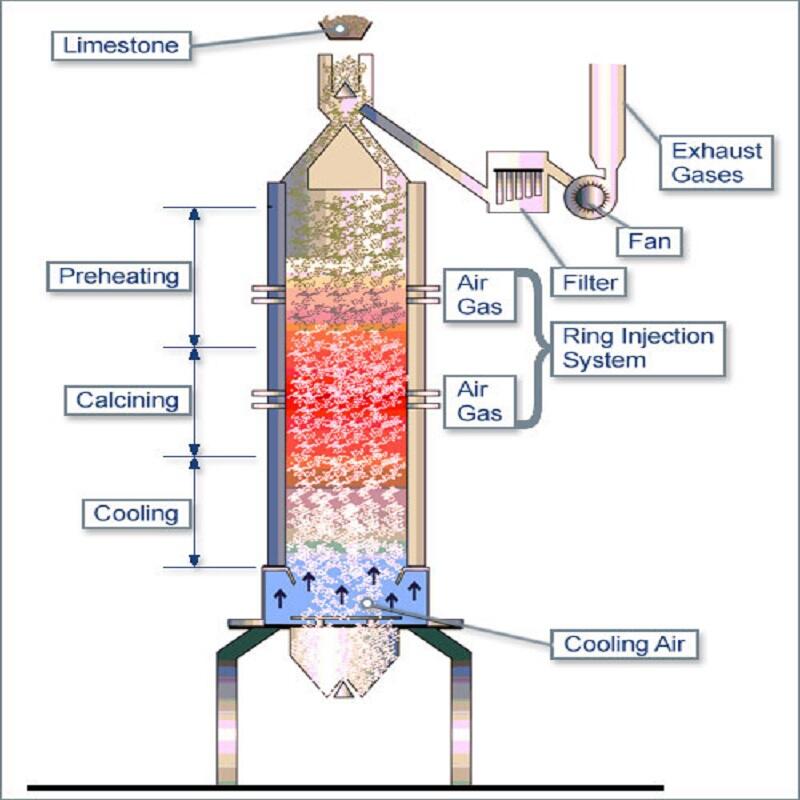

Our firm specializes in offering advanced vertical lime kiln plants that incorporate modern technology. These plants efficiently utilize cost-effective energy sources, notably repurposing initial pollutants like converter gas, blast furnace gas, and calcium carbide furnace tail gas as their primary energy inputs. By converting waste into valuable resources, this approach not only safeguards the environment but also yields high-quality lime at a reduced cost. Adopting this innovative technology can substantially enhance economic benefits for businesses.

Specifications:

| Item | Function |

| 9-19 series high pressure fan | Combustion air and secondary air in the kiln |

| Circulating gas fan | Adjust the furnace condition |

| Air compressor | reverse blow for electronic scale, distributor, and other equipment |

| Bag dust collector | Flue gas dust removal |

| Centrifugal wind fan | Auxiliary equipment of dust collector |

| Continuous bucket elevator | Finished ash-loading warehouse |

| Suspended vibrating screen | Sieve raw materials and remove impurities |

| Suspended vibrating feeder | Used in the feeding place |

| Desulfurization tower | Flue gas desulfurization, denitrification |

| Spec | Specifications and technical parameters are determined according to the size of the kiln. |

Competitive Advantage:

1. Distinctive design guarantees energy-efficient performance.

2. Innovative dust removal system ensures compliance with flue gas discharge standards.

3. Advanced automated production processes are implemented at a high level.

4. Raw materials maintain uniform size, resulting in superior product quality.

5. The mixing system features a novel design with an automatic weighing device.

6. The spraying equipment structure is uniquely designed for a uniform kiln layout.

7. Ash discharge equipment is rationalized, employing an advanced furnace condition control method.

8. Waste heat is efficiently utilized, and the layout is compact for optimal efficiency.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ