High-Capacity Large Vertical Master Lime Kiln

| Capacity: | 600-1200 t/d (adjustable) |

| Limestone Particle Size: | 30-60mm; 40-80mm |

| Fuel: | gas, oil, pulverized coal, etc. |

| Activity Degree: | 320 ml |

| Features: | various fuels available, large feed particle size, medium investment cost, large output, high automation, and energy saving. |

Overview

Inquiry

Related Products

Description:

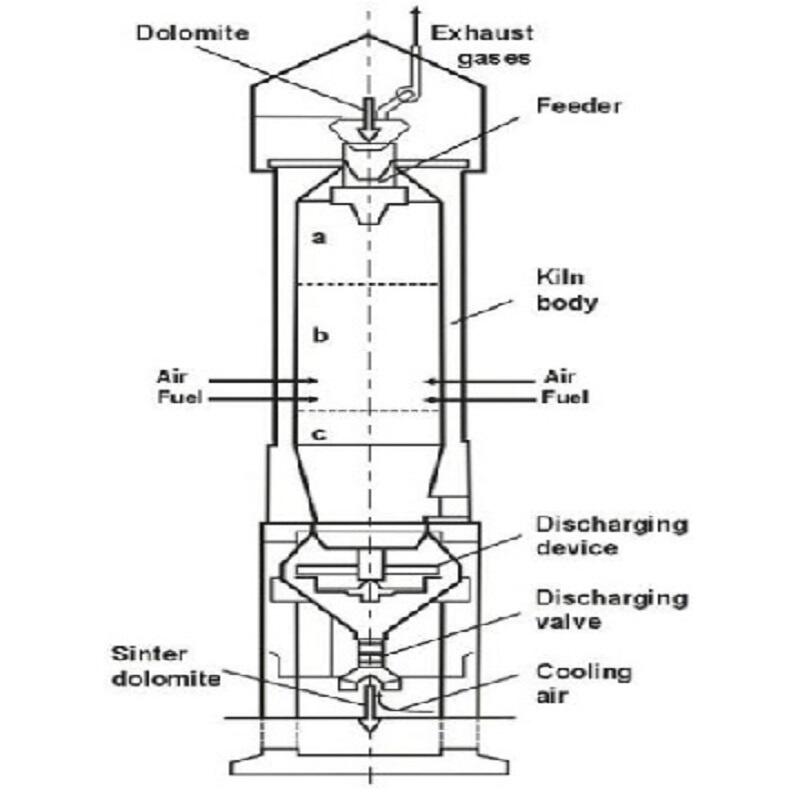

The vertical lime kiln is a device that heats limestone and fuel together to produce a high-temperature reaction and complete the firing and production of lime. Its main working principle is that the limestone stone and fuel (such as wood, coal, etc.) are layered into the vertical lime kiln, and under the combustion of the fuel, the limestone stone enters the furnace chamber layer by layer, and is constantly subjected to high-temperature pyrolysis, and releases carbon dioxide (CO2) to produce the lime (CaO) required for production.

Process Flow:

1. The loader loads the raw fuel distribution into the limestone silos and coal silos, which are transported to the mixing silos for waiting.

2. Accurately weigh the raw fuel.

3. The vibrating plotter evenly feeds and mixes the material.

4. The mixed fuel is poured into the receiving hopper on the top of the furnace and distributed in the furnace through the volute distributor on the top of the furnace.

5. When the charge moves slowly downward, it passes through the tropical zone, the forging zone, and the cooling zone. In this process, the heat is exchanged with the hot rising gas flow, and the process of limestone grain development and limestone decomposition is generated.

6. After the above steps are completed, the combustion air is cooled to 40-60 ° C, and the fuel can be unloaded onto the belt.

Competitive Advantage:

lAutomatic batching

The limestone and coal in the furnace can be accurately weighed and reasonably proportioned to save energy and reduce consumption.

lGood air tightness

Kiln masonry is constructed with thermal insulation materials that are resistant to high temperatures and low thermal conductivity.

lUniform feed

The furnace top charging equipment is composed of a receiving hopper, rotary distributor, and transmission device, and the rotary distributor carries out uniform and fixed feeding, so that the limestone and coal are distributed in point and network, the air flow is evenly distributed, and the calcination zone is stable.

lAutomatic control

The vertical lime kiln uses new automatic control technology to ensure the safe operation of key equipment such as distribution, mixing, air supply, and ash unloading.

lQuantitative air supply

The wind cap controls the speed of the air supply, which is designed by our factory to ensure a uniform air supply in the furnace and avoid the phenomenon of partial and overburning of the shaft furnace.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ