Low Investment Cost Vertical Lime Kiln For Limestone Calcination

| Capacity: | 80-400 t/d (adjustable) |

| Limestone Particle Size: | 20-40mm; 60-90mm |

| Fuel: | gas, oil, pulverized coal, etc. |

| Activity Degree: | 320 ml |

| Features: | mixed feed lime kiln, Japanese technology, low investment cost, small output, high automation, and energy saving. |

Overview

Inquiry

Related Products

Description:

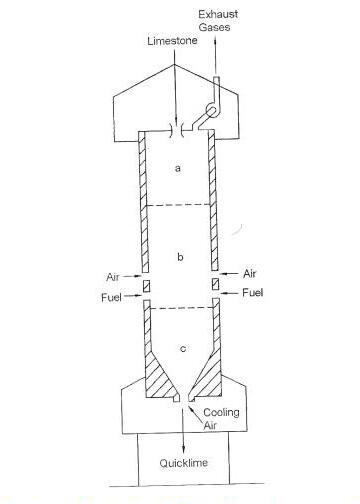

The single shaft lime kiln also referred to as the lime shaft furnace, comprises the furnace wall and a burner set on it. Positioned at the center of the shaft furnace is a cylindrical furnace core, surrounded by an annular gap between the core and the furnace wall.

Shaft lime kilns with mechanized systems serve as primary calcining equipment in cement and alumina production. These kilns boast a well-designed structure, incorporating advanced technology, a robust transmission device with significant carrying capacity, a prolonged service life, and consistent output stability. This equipment is proficient in generating high-quality lime, making it a valuable asset in industrial processes.

Specifications:

| Vertical Kiln(Effective vol)(m³) | 100-500 |

| output(t/d) | 80-400 |

| Energy consumption(KJ/kg·lime) | 910×4.1868 |

| Coal consumption(kg/t·lime) | <130 |

| Utilization factor(t/d.m3) | ≥0.85 |

| Activity degree(ml) | ≥300 |

| Calcium content of quicklime (%) | ≥90 |

| Over-burning rate of quicklime (%) | < 5-7 |

| Quick lime consumption(t/t) | 1.8 |

| CO2 concentration in flue gas (%) | 42 |

| Soot emission index(mg/Nm3) | < 10 |

Competitive Advantage:

lUniform feeding, rotating cloth

The upper feeding mechanism comprises a receiving hopper, transmission, and a rotating distributor. Material from the truck is uniformly and quantitatively delivered to the rotating distributor, facilitating thorough mixing before entry into the furnace. The circular fixed-point distribution of the rotary distributor, whether automated or manual, distributes limestone and coal in a "Dots and nets" pattern within the furnace section. This arrangement, forming a surface in the shape of "M," ensures even airflow throughout the furnace, crucial for stabilizing the calcining process.

lOptimized Air Supply, Sealing, and Ash Discharge

This segment includes a centrifugal fan, air cap, and ash unloader. Fans deliver air precisely as required, while our designed air cap ensures a uniform air supply, preventing partial burning or overburning in the shaft furnace. The ash unloader facilitates even material discharge around the furnace circumference, ensuring consistent and steady material column descent. This not only maintains furnace airflow stability and prevents gas leakage but also enhances on-site environmental conditions.

lAutomated Weighing and Consistent Batching

Accurate weighing and maintaining a proper limestone-to-coal ratio are pivotal for achieving high-quality calcination and energy efficiency in lime shaft kilns.

lEfficient Automatic Control for Safety

The lime furnace system incorporates advanced automatic control technology, optimizing key processes such as material distribution, mixing, air supply, and ash discharge. This ensures the secure operation of critical equipment, promoting safety and reliability across the entire lime production process.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ