Available Mixed Fuel Double Beam Design Lime Kiln For Lime Production Line

| Capacity: | 100-600 t/d (adjustable) |

| Limestone Particle Size: | 30-60mm; 40-80mm |

| Fuel: | gas, oil, pulverized coal, etc. |

| Activity Degree: | >320 ml |

| Features: | mixed fuel is available (gas-oil, gas-coal, etc.), low investment cost, medium output, high automation, and high activity value. |

Overview

Inquiry

Related Products

Description:

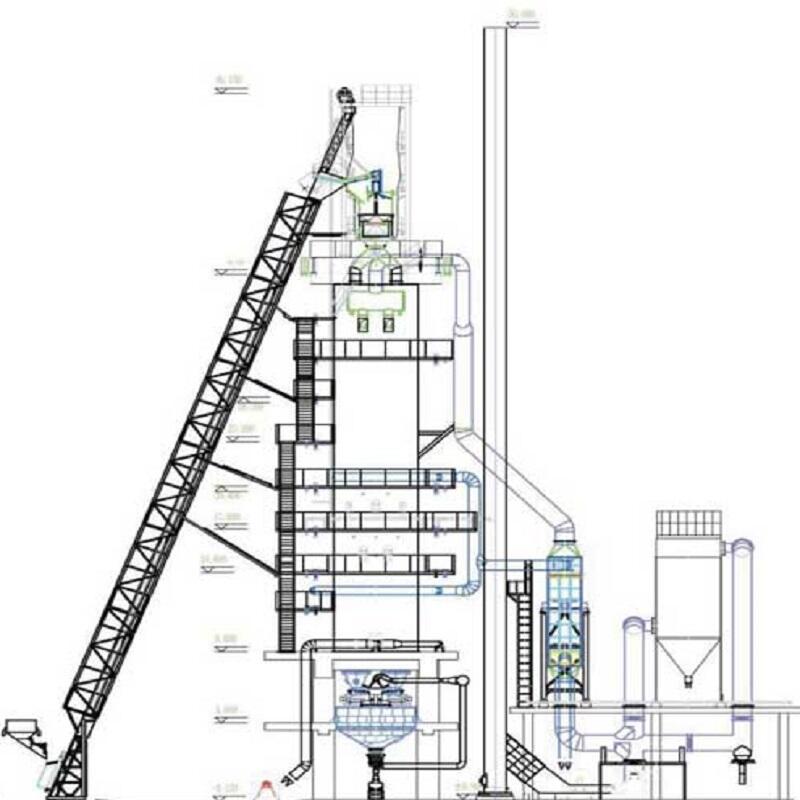

The Twin-Beam Lime Kiln offers benefits such as minimal heat consumption, elevated lime activity, robust fuel adaptability, uncomplicated structure, and cost-effectiveness. Ideal for utilizing blast furnace gas and coke oven gas in the iron and steel industry, as well as employing calcium carbide furnace tail gas or mixed combustion with pulverized coal in the chemical and calcium carbide sector. This aims to enhance lime quality and achieve energy efficiency, ensuring the production of high-quality active lime.

Structural Characteristics:

The kiln design incorporates a quasi-rectangular body featuring upper and lower burner beams. Positioned above the limestone reserve area, the upper kiln gas extraction pipe enables preheating between the extraction pipe and the upper burner beam. High-temperature kiln gas preheats limestone before entering the calcination area, ensuring uniform calcination into active lime, adjusted according to quality and yield requirements.

Limestone is introduced through the kiln top distribution device, evenly distributed, with sealing doors preventing air entry during feeding. The system includes storage, preheat, calcination, post-calcination, and cooling belts. The two-layer burner beam, a crucial technical element, is cooled by thermal oil, housing adjustable burners for cross-section heating. Uniform negative pressure is maintained through upper suction pipes, ensuring optimal combustion efficiency, low percolation rates, and high lime activity.

The upper layer's kiln gas extraction pipe and evenly distributed openings on the lower side maintain uniform negative pressure for optimal combustion efficiency. A lower suction beam in the cooling belt draws cold air to cool the finished ash. The kiln body, consisting of only the 2-layer suction beam, 2-layer burner beam, and flight mechanism, exhibits a simple structure with minimal maintenance, low operating costs, and reduced energy consumption.

Operational control, facilitated by a PLC control system, ensures simplicity and ease of mastery. Embrace innovation with our kiln design, ensuring efficiency, uniformity, and cost-effectiveness in lime production.

Competitive Advantage:

lThe three-way pressure system has undergone multiple enhancements to effectively prevent excessive air from entering the calcination belt, avoiding interference with the calcination temperature. This ensures that the heat carried by the lime flowing from the calcination belt to the rear calcination belt maintains an even distribution, leading to a significant reduction in power and heat consumption. Consequently, this improvement enhances lime quality, with a generation and overburning rate of approximately 5%-6%.

lThe investment is economical, with a steel structure requirement of around 370 tons for 500t/d and 480 tons of resistant material. Material specifications are standard, eliminating the need for special-shaped bricks, and the system equipment is comparatively less than other kiln types.

lThe operation is straightforward, boasting a high operational efficiency and low production costs.

lDemonstrating high production flexibility, it can manufacture lime products catering to the diverse needs of various industries.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ