High Activity Value Annular Shaft Kiln Based On Chinese Technology(CASK)

| Capacity: | 100-300 t/d (adjustable) |

| Limestone Particle Size: | 30-60mm; 40-80mm |

| Fuel: | gas, pulverized coal, etc. |

| Activity Degree: | >320 ml |

| Features: | based on Chinese technology, large feed particle size, low price, small output, high automation, and high activity value. |

Overview

Inquiry

Related Products

Description:

The parameters of the Chinese Annular Shaft Kiln are finely tuned to achieve unparalleled performance. From temperature control to rotation speed, each aspect is calibrated with precision, allowing for versatile applications across diverse industries. This kiln comes in multiple models, catering to specific needs and scaling requirements, making it a versatile asset for businesses.

Beyond its technical prowess, the Chinese Annular Shaft Kiln has earned its stripes in practicality. Its uses span a wide spectrum – from the production of cement to the calcination of minerals and beyond.

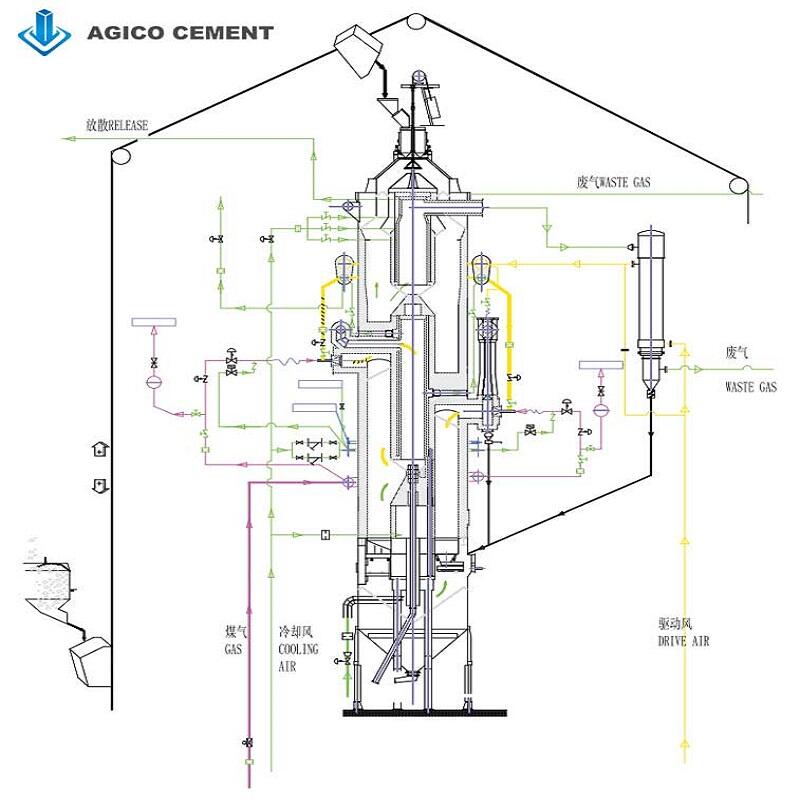

Process Flow:

The 500-ton annular shaft lime kiln serves as an exemplary model characterized by a well-defined process flow. It incorporates upper and lower layers of burners, each tier featuring six evenly spaced burners positioned 3.9 meters apart at a 30-degree interval. The lower burners delineate the countercurrent and downstream calcination zones, featuring combustion chambers with arch bridges made of refractory materials for the uniform distribution of hot gas throughout the material bed.

Constructed with inner and outer cylinders, the annular sleeve active lime kiln establishes an annular space for limestone calcination. This space is divided into preheating, countercurrent calcination, cocurrent calcination, and cooling zones, maintaining optimal conditions for consistent limestone calcination. The upper inner sleeve, suspended at the top, and the lower inner sleeve, situated in the middle, are fabricated from boiler steel plates with refractory materials to facilitate efficient cooling.

This meticulous design ensures uniform pressure, airflow, and temperature distribution, enhancing the uniformity of limestone calcination, improving product quality, and reducing unit consumption. The kiln is segmented into three distinct zones: a 9-meter preheating zone (90-140°C to 850-900°C), an 11-meter calcining zone (850-900°C to 900-950°C), and a 7-meter cooling zone (900-950°C to 80-130°C).

In the preheating zone, waste heat is minimized through an upper inner sleeve and heat exchanger design, utilizing low-calorific gas or high-CaCO3 limestone. The calcination zone, constituting 70-80% of the process, primarily operates in the countercurrent calcination zone, while the downstream calcination zone handles the remaining 20-30%. The cooling zone efficiently exchanges heat with cold air, reducing lime temperature before discharge (80-130°C). This innovative annular shaft lime kiln not only optimizes production efficiency but also demonstrates adaptability to various raw materials, setting it apart from traditional lime kilns.

Competitive Advantage:

lThe annular shaft lime kiln has transitioned from its original positive pressure operational mode to a negative pressure operation, eliminating flue gas and dust overflow for enhanced compliance with environmental protection requirements.

lMultiple combustion chambers are strategically arranged in a staggered fashion on the upper and lower layers. Each chamber is linked to the inner cylinder via an arch bridge constructed from refractory masonry. This design ensures the uniform distribution of high-temperature smoke generated during combustion, facilitating even heating of the stone.

lOptimal lime calcination quality and activity are achieved through a combination of calcination stages, including the preheating zone, upper countercurrent calcination zone, middle countercurrent calcination zone, and lower co-flow calcination zone.

lThe inner cylinder is utilized to preheat primary combustion air, and a portion of the flue gas is recycled through a heat exchanger to further preheat and reduce overall energy consumption.

lWith a high degree of automation, straightforward operation, and convenient adjustment features, this annular shaft lime kiln represents a technologically advanced and user-friendly solution.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ