Double-Beam Lime Kiln With Double Combustion Chambers For Industrial Lime Production

| Capacity: | 100-600 t/d (adjustable) |

| Limestone Particle Size: | 30-60mm; 40-80mm |

| Fuel: | gas, oil, pulverized coal, etc. |

| Activity Degree: | >320 ml |

| Features: | mixed fuel is available (gas-oil, gas-coal, etc.), low investment cost, medium output, high automation, and high activity value. |

Overview

Inquiry

Related Products

Description:

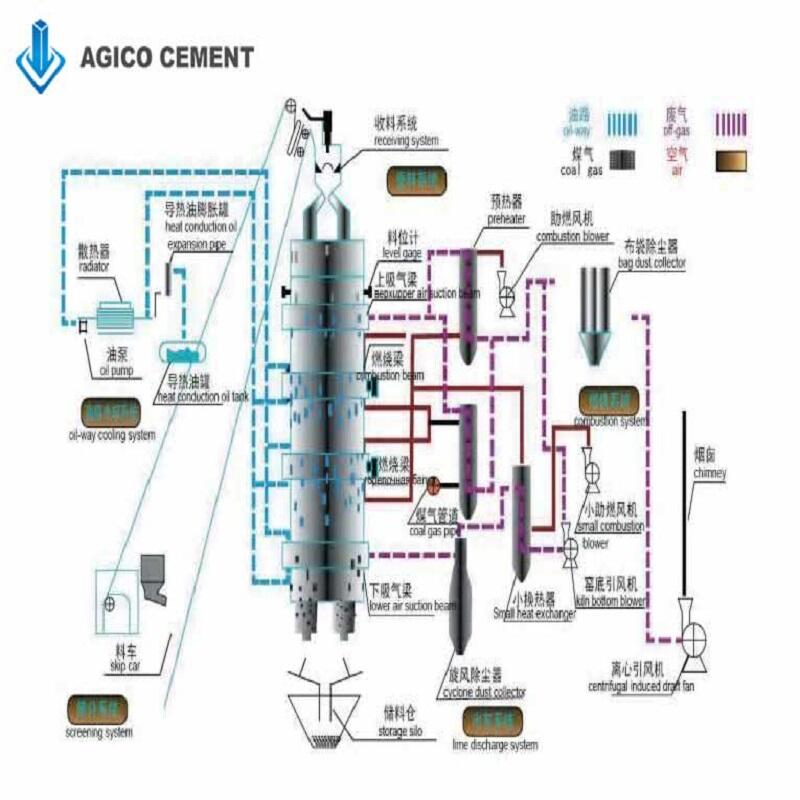

The Double-Beam Lime Kiln has the advantages of low heat consumption, high lime activity, strong fuel adaptability, simple structure, and low cost. It is suitable for the use of blast furnace gas and coke oven gas in the iron and steel industry and the use of calcium carbide furnace tail gas or mixed combustion with pulverized coal in the chemical and calcium carbide industry to achieve the purpose of improving the quality of lime and energy saving, calcined high-quality active lime.

Structural Characteristics:

The kiln design features a quasi-rectangular body with upper and lower burner beams. The upper kiln gas extraction pipe, positioned above the limestone reserve area, facilitates preheating between the extraction pipe and the upper burner beam. High-temperature kiln gas preheats limestone before entering the calcination area, where uniform calcination into active lime occurs, adjusted based on quality and yield requirements.

Limestone enters through the kiln top distribution device, evenly distributed, with sealing doors preventing air entry during feeding. The system comprises storage, preheat, calcination, post-calcination, and cooling belts. The two-layer burner beam, a key technical element, is cooled by thermal oil, housing adjustable burners ensuring cross-section heating. Uniform negative pressure is maintained via upper suction pipes, ensuring optimal combustion efficiency, low percolation rates, and high lime activity.

The upper layer's kiln gas extraction pipe and evenly distributed openings on the lower side maintain uniform negative pressure for optimal combustion efficiency. A lower suction beam in the cooling belt draws cold air to cool the finished ash. The kiln body, comprising only the 2-layer suction beam, 2-layer burner beam, and flight mechanism, exhibits a simple structure with minimal maintenance, low operating costs, and reduced energy consumption.

Operational control, facilitated by a PLC control system, ensures simplicity and ease of mastery. Embrace innovation with our kiln design, ensuring efficiency, uniformity, and cost-effectiveness in lime production.

Competitive Advantage:

lThe three-way pressure system has been adopted and improved many times to effectively prevent excess air from entering the calcination belt to interfere with the calcination temperature, so that the heat carried by the lime flowing from the calcination belt to the rear calcination belt is its own average, thus effectively reducing the power consumption and heat consumption, improving the quality of lime, and the generation and overburning rate is about 5%-6%.

lThe investment is low, the steel structure used for 500td is about 370 tons, the resistant material is 480 tons, the material requirements are general, there is no special-shaped brick, and the system equipment is less than other kiln types.

lThe operation is simple, the operation rate is high, and the production cost is low.

lHigh production flexibility, can produce lime products required by all walks of life.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ