SubsidiaryNo.1:Cement International Engineering, a manufacturer of Special Vertical Cement Kiln machines. Horizontal cement kiln what do you ask them, many. Actually, my work is ultra mega helping cement production machine. Cement, we use in building Many things like Houses, Roads, Bridges. Construction. One of the most important places where it is quite prominent as through its other very safe and strong building are made like blocks, pavements etc. But how, exactly, do Cement International Engineering inside cement kiln work are why are they so beneficial for the planet?

Know named vertical cement using it always Tower this is because the stand up! Building space is smaller compare to laid on the ground/pyramid shaped kiln. It also allows the rocks, limestone and shale to fall inside the kiln. As the rocks go in, they get mixed with hot air. Which are subsequently converted into cement by the particular process up and down kilns also assistance additional heat than chiseled kilns, spending less on electricity and going charges. As a result, it is quicker. They also contain a great deal fewer moving parts than your ordinary flat kiln, which implies they are easier to take care of and keep.

And so, without further ado, we move on the “How” — How vertical cement kilns are good for the environment. These vehicles have a saving grace—they are way below permissible carbon emissions. Emissions of carbon mean gases escaping through the burning of things like coal and oil. In fact, cement plants are one of the largest producers of carbon emissions in the entire world! That is a huge hit to the planet. But flue gas from the vertical cement kiln burned with less fuel and less carbon dioxide, a key ingredient in creating carbon emissions. These absorbent chemicals are often used in Cement International Engineering inside cement kiln systems with coal to replace more expensive alkalis, such as sunflower seed, rice husks (metals free). The importance of renewable sources of fuel on our planet is foremost.

Rutile titanium Capacity is also high, but the fuel efficiency, there has not been more likely burned outside as a horizontal cement kiln. Most common fuel used in cement manufacturing is coal, and waste material such as gas or even type of kilns (vertical) it can run on different type of fuels. This flexibility enables Cement International Engineering the rotary cement kiln to function significantly a lot more efficiently. Some kilns are equipped for burning waste heat from the cement-making process to heat the kiln. These, not only conserves energy but also helps maintain zero wastage thus promoting sustainability and eco-friendliness as well. Bringing a greener tomorrow now : Y et one more such instance because the Vertical kilns assist us to rehearse the tempest we are a part of Unami we all belong.

The truth is those using Cement International Engineering the rotary cement kiln will really produce an impact within their field of operation as well as consider a few the market share on their own. For a fraction of the space required and burning less fuel which is cheaper, therefore more profit. Good for the Businesses! Moreover, the high heated and chemically reacting cement too can be produced in a speedier way than others. The faster cement plants turn out more cement, the better they can satisfy customer needs and thus boost their business. Because for this reason, Vertical top to bottom kilns is best alternative for cement produce.

A must for sustainable cement making as we grapple with the climate emergency, addressing carbon emissions is crucial. Vertical Kilns Vertical kilns have found one of the methods in green solution meant for saving the environment and also the discriminating businessmen. Calling us to build a new world, they do so through the products of companies such as Cement International Engineering cement kiln for sale. Technology allows us to develop a more sustainable future that we can live in.

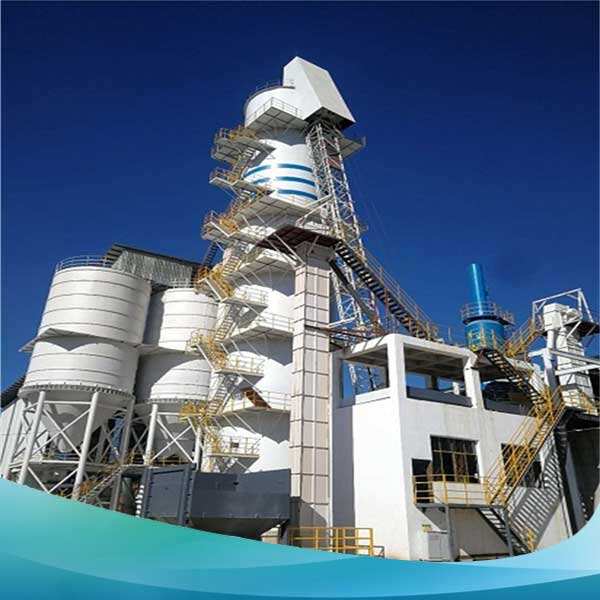

For long time, AGICO has had a professional technical team, mature production technology, rich production experience, forming complete set shaft kiln production technology management systems, making energy-saving environmental-protective lime shaft kiln technology perfect. technology characterized by that are low-cost investment, a superior degree of automation, high product quality, low energy consumption, long life of the furnace, Vertical cement kilnprotection. is widely used in metallurgy, nonferrous chemical, metals, construction materials, as well as other industries, deep processing industries as well as other industries.

company has focused on program design, engineering design, special equipment supply as well as installation and commissioning training of employees, oven services, furnace start-up, production reaching of energy-saving and green lime shaft kiln. company has built activated Vertical cement kilnwith various sizes such as 150m3, 170m3, 250m3, 350m3, etc. kilns were opened successfully had remarkable effect! Utilizing advanced technology of coke lime shaft kiln the gas-burning lime shaft furnace has been developed, and agreements for design have been concluded with numerous companies.

AGICO a professional technical team specializes in EPC turnkey projects that cover design, manufacture installation, debugging maintenance, many other Vertical cement kiln. AGICO offers a full range on-sales pre-sales services, as well after-sales technical assistance.

Since more than 20 years, we've been involved research, development, design, production, installation lime kilns that Vertical cement kilnfriendly fully automated, low investment, energy consumption is low, etc. are trusted for our excellent reliable service, and long-lasting lime Kiln.