How Lime Calcination is understood?

Calcinations are very special situation for the product, which heat is used to make it complete and even remove impurities but after, it comes with a post-heat treatment that has even clearer impurities. Namely, Cement International Engineering lime calcination plant is the process of heating limestone to generate lime used as a key input for many other industries.

However, there are several advantages in lime calcination described above that can be brought out from this process. When made from high-quality limestone, lime produced by this process can be utilized by various industrial fields where purity is a concern. Also importantly, lime is much cheaper than alternatives saving businesses huge amounts of money. Moreover, the performance of lime in industrial processes leads to greater efficacy making it possible to achieve higher production rates and cost efficiency.

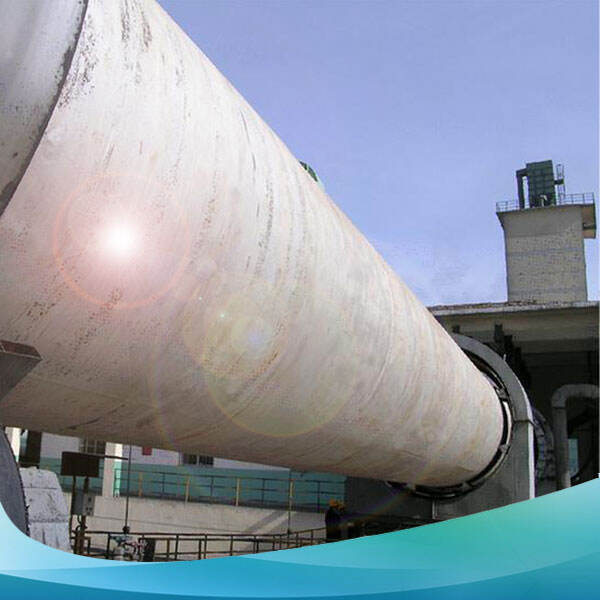

Within recent years there have been different developments within the lime calcining process. Cement International Engineering calcination of lime has opened a new chapter in the production process that now enjoys improved speed as well. New technologies used in kilns include vertical shafts (see also vertical shaft kiln), rotary kilns and fluidized bed reactors resulting in high quality industrial limes.

Safety issues during Lime Calcinations

Limestone calcinations represents one example of typical high temperature processes – not much different from any typical minerals during production stage involving lime chemicals. These buildings need practical protection against fires or explosion risks too. This calls for use appropriate tools alongside adopting safety measures while educating employees on safe work practices.

Most compounds derived from lime are versatile substances hence having diverse applications within industries like construction, agriculture; water treatment or mining etc. While it serves primarily as a source material for making mortar and plaster used in construction, it also plays an important role in agriculture where it is used to amend soil pH for improved crop yields. In addition, lime is an inevitable ingredient during metal extraction from the ore as well as in pH control water treatment processes aimed at high-quality provision.

Lime comes in different forms which helps to have different effects on specific applications. Once hydrated lime is mixed with water, the mixture becomes slurry commonly used for stabilizing soils and treating wastewater as well as making concrete for construction purposes. Dolime acts as a raw material for quicklime production by way of high temperature kiln calcinations of stone sizes up to 40mm or dolomitic lime particles whose size range lies below 8mm hence only applicable in some industrial applications like sugar refinery etc.). It is also important to note that dolomite lime can be considered as one kind of the main usage with respect to the dolomitic member which has been changed into a product referred to “dolomite” and it can actually be utilized as another name such regular or agricultural through lignin solar Dioxide used with magnesium over calcite present carbonate rocks while obtaining carbon dioxide right from air.

Total rideshare services are offered for Lime users

These companies that deal with lime manufacturing avail such to their consumers for various reasons, including ensuring customer satisfaction. Cement International Engineering limestone calcination services and involves product delivery at the consumer point where quality is tested in line with customer need while immediate assistance is given by the customer contact center on any arising matters.

AGICO owns professional technical team, specializing in EPC turnkey projects cover design, manufacture and lime calcination process, as well as debugging maintenance, and more. offer complete pre-sales service, on-sales service, and an after-sales service, which provides highest level technical support satisfy your needs.

company has focused on the design engineering design, special equipment delivery, installation lime calcination process, personnel training, oven services, furnace start-up, and production reaching energy efficient environmentally friendly lime shaft kiln. We have built successively activated lime shaft kilns with volumes of 150m3,170m3 200m3, 250m3 350m3 500m3, etc. These then successfully opened and effect was impressive! The gas-burning furnace was created by using the technology that had matured in the coke lime shaft. Design contracts were concluded with several companies.

For long time, AGICO has had a professional technical team, mature production technology, rich production experience, forming complete set shaft kiln production technology management systems, making energy-saving environmental-protective lime shaft kiln technology perfect. technology characterized by that are low-cost investment, a superior degree of automation, high product quality, low energy consumption, long life of the furnace, lime calcination processprotection. is widely used in metallurgy, nonferrous chemical, metals, construction materials, as well as other industries, deep processing industries as well as other industries.

Since over 20 years have been dedicated lime calcination processresearch, design manufacturing installation lime-kiln. is full-automatic with the lowest cost f investment. e are trusted for high-quality and perfect service, and long-lasting lime Kiln.