Are you curious about lime processing plants and their benefits? This article will help you understand advantages innovation, safety usefulness and quality surrounding these Cement International Engineering lime manufacturing process.

Lime processing plants from Cement International Engineering offer numerous advantages, including ability to convert raw limestone into several different products. The versatility of these Cement International Engineering plants allows them to generate range of products. These cater to different consumers' needs. Additionally the use of lime as an agricultural product aids in the growth of plants. It neutralizes soil acidity. Lime also provides necessary nutrients like calcium and magnesium.

In recent times, technology has advanced immensely. Lime processing industry has not been left behind. Lime processing plants' innovative technology ensures they produce high-quality lime solutions for industrial or agricultural use. These innovations include automation in manufacturing process. This enables increased efficiency reduced workloads and employee safety. The limestone processing plant of Cement International Engineering also have elaborate research facilities. These help produce improved products regularly.

Safety is priority in any manufacturing plant and lime processing plants have stringent measures in place. Given lime's corrosive nature employees must wear protective gear when working with it. The Cement International Engineering plant area should also be adequately ventilated. This reduces potential lime dust inhalation. The use of modern-day safety equipment and procedures reduces the chance of accidents significantly.

Lime is versatile product with several agricultural applications, such as soil conditioning and disinfecting animal bedding. Lime's high alkalinity neutralizes soil acidity. This creates an environment that plants can grow in. When applied to fields lime reduces the possibility of soil-borne diseases and pests. This improves crop yields.

Lime is also used industrially, with its most common use being in water treatment. Water treatment involves the reduction of water acidity. This often makes water corrosive to water pipes in industries. The Cement International Engineering lime production from limestone breaks down wastewater solids. This makes the water safer to discharge into the environment.

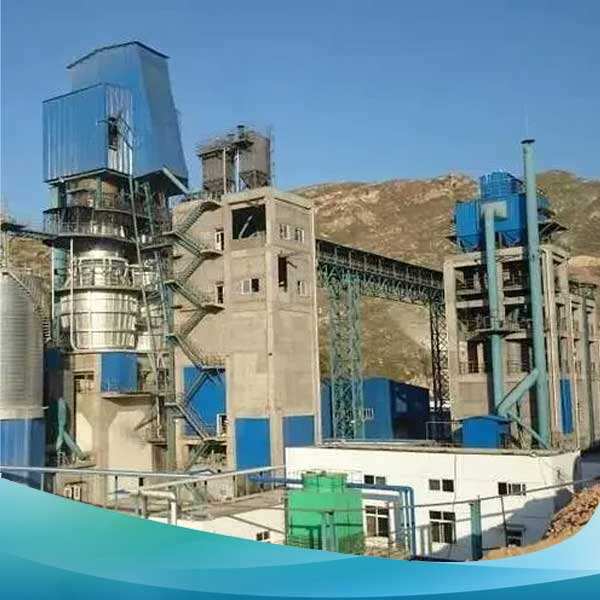

Over past 20 years, have been committed the research, development design, manufacturing lime processing planta lime kilns and its environmental protection fully automated, low investments, a low consumption energy, etc. The lime kiln we use has long-lasting service life you can trust us because of our perfect service and high-quality lime Kiln.

AGICO home to skilled technical team, specializing in EPC turnkey projects, which include design, lime processing plant, installation, debugging, maintenance, as well as other services. AGICO offers full range of on-sales pre-sales services in addition to after-sales technical support.

company has been involved in design of programs, engineering design, special equipment provision, installation and commissioning, oven training employees starting up furnaces, as well as production reaching of an energy-efficient and sustainable lime shaft kiln. company has built activated kilns with various sizes that include 150m3, 170m3, 200m3, 350m3, 500m3, etc. kilns were opened successfully and produced stunning effect! Utilizing lime processing plant that is mature in the coke lime shaft kiln the gas-burning lime shaft is kiln has been developed, contract agreements have been signed withnumerous companies.

long time, AGICO has had a professional technical team, mature production technology, rich production experience, forming a complete set of shaft kiln production technology management systems, making energy-saving and environmental-protective lime shaft lime processing planttechnology perfect. This technology has low cost of investment, high quality of automation, superior product quality. also low energy usage as well as an extended furnace life. It has been widely used in metallurgy non-ferrous chemical industries, metals, building materials, as well as other sectors, such as deep processing, etc.