High Efficient Lime Rotary Kiln With Advanced Production Process

| Capacity: | 200-1200 t/d (adjustable) |

| Limestone Particle Size: | 20-40mm |

| Fuel: | gas, pulverized coal, etc. |

| Activity Degree: | 360-400 ml |

| Features: | small feed particle size, high price, high activity value, various fuels available, high automation, and low heat consumption. |

Overview

Inquiry

Related Products

Description:

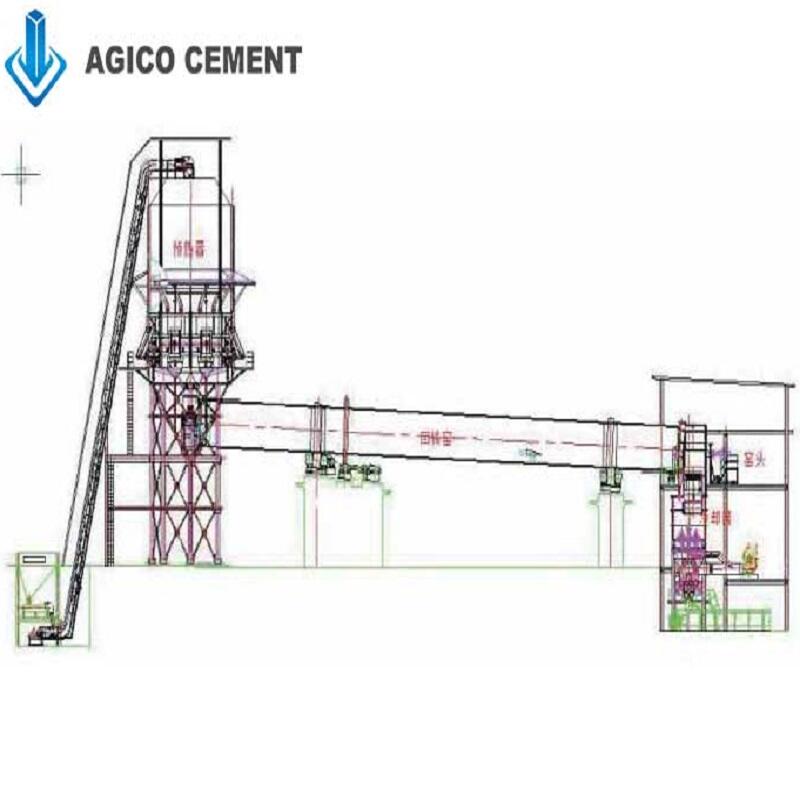

The lime rotary kiln, also recognized as a rotary kiln, is a dynamic calcination device within the realm of building materials equipment. Noteworthy advantages encompass significant production capacity, noise-free operation, and minimal overall energy consumption. Functioning as a pivotal tool in lime production, it holds substantial industrial value, reflecting a heightened current demand. Lime finds broad utility across construction, building materials, metallurgy, chemical industry, light industry, environmental protection, medicine, and agriculture. Especially in sectors like steelmaking, ironmaking, sintering, copper, aluminum smelting, and more, lime plays a vital role as a slagging agent, solvent, or sintering material. The lime rotary kiln's extensive applications underscore its versatility and importance in diverse industrial settings.

Specifications:

| Specifications of lime rotary kiln | ||||||||||||

| Capacity (t/d) | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 750 | 800 | 1000 | |

| Product | Active lime, Calcined dolomite | Active lime, Calcined dolomite | Active lime, Calcined dolomite | Active lime, Calcined dolomite | Active lime, Calcined dolomite | Active lime, Calcined dolomite | Active lime, Calcined dolomite | Active lime, Calcined dolomite | Active lime, Calcined dolomite | Active lime, Calcined dolomite | Active lime, Calcined dolomite | |

| Preheater | Circular vertical preheater or polygonal vertical preheater | Circular vertical preheater or polygonal vertical preheater | Circular vertical preheater or polygonal vertical preheater | Circular vertical preheater or polygonal vertical preheater | Circular vertical preheater or polygonal vertical preheater | Circular vertical preheater or polygonal vertical preheater | Circular vertical preheater or polygonal vertical preheater | Circular vertical preheater or polygonal vertical preheater | polygonal vertical preheater | polygonal vertical preheater | polygonal vertical preheater | |

| Rotary kiln | size(m) | Φ2.5×40 | Φ2.8×42 | Φ3×46 | Φ3.2×50 | Φ3.5×54 | Φ3.6×56 | Φ3.8×58 | Φ4×60/Φ4.2×50 | Φ4.3×58 | Φ4.3×64 | Φ4.8×68 |

| Effective volume (m3) | 142 | 190 | 235 | 292 | 390 | 430 | 505 | 575/548 | 670 | 738 | 1005 | |

| Temperature (℃) | 1350/1250 | 1350/1250 | 1350/1250 | 1350/1250 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | |

| Cooler | Square vertical cooler | Square vertical cooler | Square vertical cooler | Square vertical cooler | Square vertical cooler | Square vertical cooler | Square vertical cooler | Square vertical cooler | Square vertical cooler | Square vertical cooler | Square vertical cooler | |

| Fuel | Gas,pulverized coal | Gas,pulverized coal | Gas,pulverized coal | Gas,pulverized coal | Gas,pulverized coal | Gas,pulverized coal | Gas,pulverized coal | Gas,pulverized coal | Gas,pulverized coal | Gas,pulverized coal | Gas,pulverized coal | |

| Heat rate(KJ/KgC3O) | 5300/5000 | 5300/5000 | 5300/5000 | 5300/5000 | 5225 | 5225 | 5100 | 5100 | 4810 | 4810 | 4810 | |

Working Principle:

Limestone enters the kiln through the chute positioned at its end. Through the kiln's tilt and gradual rotation, the limestone moves along one side's circumference, progressing from the kiln's end to its head along the axis on the opposite side. Fuel is fed into the kiln through the burner at the end, undergoes combustion, and transmits the generated heat to the limestone through radiation, convection, and conduction. As the limestone undergoes calcination, transforming into quicklime during this process, it is expelled from the kiln's end. Simultaneously, the high-temperature flue gas is directed into the dust removal system from the kiln's end. This mechanism ensures the efficient transformation of limestone into quicklime while managing the disposal of high-temperature flue gas.

Competitive Advantage:

Cutting-edge Technology: The primary propulsion system now incorporates advanced AC frequency conversion speed regulation technology. This technology, distinguished from traditional electromagnetic and DC speed regulation, excels in energy efficiency, eco-friendliness, a broad speed regulation range, precise speed control, and stable operation.

Accurate and Reliable Installation: After welding the supporting wheel and retaining wheel's supporting device base and relieving welding stress through vibration aging treatment, large vertical lathes and boring/milling machines ensure the machining accuracy, shape, and position tolerance of each part. This method significantly improves the installation precision and reliability of the entire system.

Effortless Operation: Addressing issues like kiln tail return materials and common dust leakage found in conventional rotary kilns, the kiln head and end sections underwent comprehensive structural optimization. This design guarantees smoother and more seamless material transportation, aligning with the specific characteristics of limestone and its calcination process requirements.

Uniform Quality: The limestone undergoes even heating, leading to consistent product quality and a low over-burnt rate. This makes it especially suitable for the calcination of highly active lime for steelmaking.

Adaptable Process Configuration: The incorporation of a vertical preheater at the kiln's end allows full utilization of high-temperature flue gas from the lime rotary kiln. This preheats the limestone from ambient temperature to the initial decomposition state, enhancing product activity and facilitating transportation and storage.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ