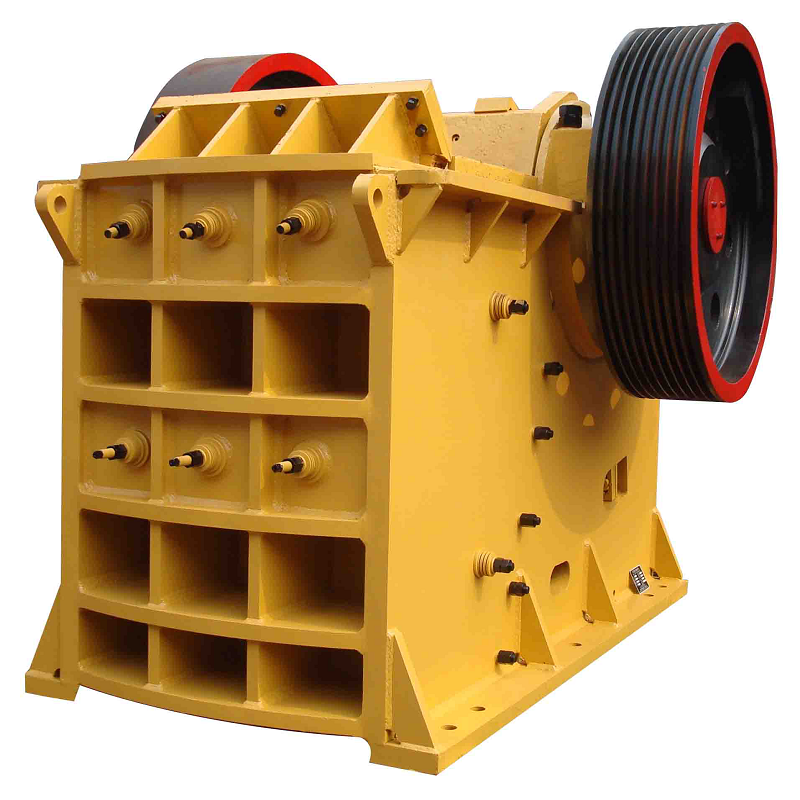

Precision Limestone Jaw Crusher For Sale

| Model: | PE, PEX |

| Motor Power: | 15~200kw |

| Capacity: | 12~600 t/h |

| Material: | river pebbles, granite, limestone, etc. |

Overview

Inquiry

Related Products

Description:

A jaw crusher, suitable for crushing ores and rocks under 250 MPa, serves as a primary or secondary crusher in the cement and lime industries. Classified by feeding port width into large, medium, and small types. AGICO, a leading Chinese manufacturer, offers PE and PEX jaw crushers known for simplicity, reliability, and easy maintenance.

The structure of jaw crusher mainly includes frame, eccentric shaft, flywheel, moving jaw plate, fixed jaw plate, adjusting the seat and so on. Among them, the frame is the support structure of the whole equipment, the eccentric shaft and the flywheel are the main components to provide power, the moving jaw plate and the fixed jaw plate are the main working parts of the broken material, and the adjusting seat is used to adjust the size of the discharge port.

The jaw crusher is driven by the motor to rotate the eccentric shaft, so that the movable jaw plate does periodic reciprocating movement, to break the material falling into the crushing chamber. When the moving jaw plate is close to the fixed jaw plate, the material is squeezed; When the moving jaw plate is far away from the fixed jaw plate, the broken material is discharged from the crushing chamber. By repeating this process over and over again, the material is eventually broken to the desired particle size.

Specifications:

| Model | Specification | Weight | Capacity | Inlet Size | Outlet Size | Power | Dimension |

| (t) | (t/h) | (mm) | (mm) | (kw) | (mm) | ||

| PE | 250×400 | 3.1 | 5月20日 | <210 | 20-80 | 18.5 | 2060x1261x1413 |

| 320×500 | 4.73 | 10-38 | <270 | 30-90 | 30 | 1500x1500x1438 | |

| 400×600 | 6.9 | 14-65 | <350 | 40-160 | 30 | 1700x1732x1596 | |

| 400×600 | 6.5 | 17-60 | ≤350 | 40-100 | 30 | 1680x1710x1601 | |

| 450×1200 | 16 | 50-100 | <380 | 50-120 | 75 | 2200x2360x1980 | |

| 500×750 | 12.07 | 40-95 | <425 | 50-100 | 55 | 2200x1916x1970 | |

| 600×900 | 17.67 | 60-200 | <500 | 75-200 | 75 | 2350x2280x2390 | |

| 750×1050 | 23.42 | 80-200 | <630 | 80-180 | 90 | 3000x2466x2590 | |

| 750×1060 | 24 | 90-260 | <630 | 80-200 | 90 | 3000x2466x2592 | |

| 900×1200 | 52 | 140-280 | <750 | 95-220 | 110 | 3380x2870x3330 | |

| 1200×1500 | 101 | 400-800 | <1020 | 150-300 | 200 | 4200x3300x3500 | |

| PEX | 150×750 | 4 | 8-35 | <120 | 10-40 | 15 | 1480x1630x1040 |

| 175×750 | 4.5 | 10-35 | <140 | 15-50 | 18.5 | 1460x1630x1170 | |

| 250×750 | 5.824 | 15-35 | <210 | 15-50 | 30 | 1600x1744x1380 | |

| 250×1000 | 7.032 | 16-51 | <210 | 15-50 | 37 | 1600x1992x1380 | |

| 250×1200 | 9.1 | 20-60 | <210 | 15-50 | 45 | 1680x2200x1405 |

Competitive Advantage:

lExceptional Dependability

Crafted with cutting-edge manufacturing techniques, our crusher employs top-tier materials. Notably, the dynamic boring assembly features high-quality steel castings, while the robust eccentric shaft undergoes precision forging, ensuring unparalleled reliability and longevity.

lEnhanced Structural Integrity

Utilizing finite element analysis, the cast steel bearing housing seamlessly integrates with the frame, significantly boosting the radial strength. This results in a sturdier equipment structure, elevating its overall strength.

lEfficient and Secure Adjustment

Designed with a symmetrical "V" shape chamber and a wedge adjusting mechanism for the discharge opening, adjustments are now simpler, safer, and faster, enhancing user experience and safety.

lRobust Load Capacity

Empowered by larger and more resilient eccentric shaft bearings and toothed guards, our crusher boasts superior load-carrying capabilities, enabling higher throughput and extended service life.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ