Annular Shaft Lime Kiln For High-Yield And Eco-Friendly Operations (ASK)

| Capacity: | 300/500/600 t/d (adjustable) |

| Limestone Particle Size: | 30-60mm; 40-80mm |

| Fuel: | gas, pulverized coal, etc. |

| Activity Degree: | >360 ml |

| Features: | an alternative to Maerz kiln, large feed particle size, high price, slightly higher energy consumption, and high activity value. |

Overview

Inquiry

Related Products

Description:

The annular shaft lime kiln stands as an advanced lime production facility in China. Employing co-current calcination within its annular shaft, this kiln yields lime with superior activity, heightened thermal efficiency, and reduced energy consumption compared to rotary kilns, Fukas kilns, and similar counterparts. Notably, it boasts easy maintenance, and a high operating rate, and accommodates a broad range of raw materials with a compact footprint. The lime undergoes calcination in the annular space, ensuring uniform air distribution without the need for kiln cooling equipment, resulting in a low failure rate and simplified maintenance.

The entire process operates under negative pressure, contributing to environmental preservation and minimizing sulfur (S) content in the burnt lime. This lime kiln has gained increasing recognition, particularly among domestic large and medium-sized metallurgical enterprises. Its applications span diverse industries such as metallurgy, chemical production, papermaking, and building materials, reflecting its growing popularity and effectiveness.

Process Flow:

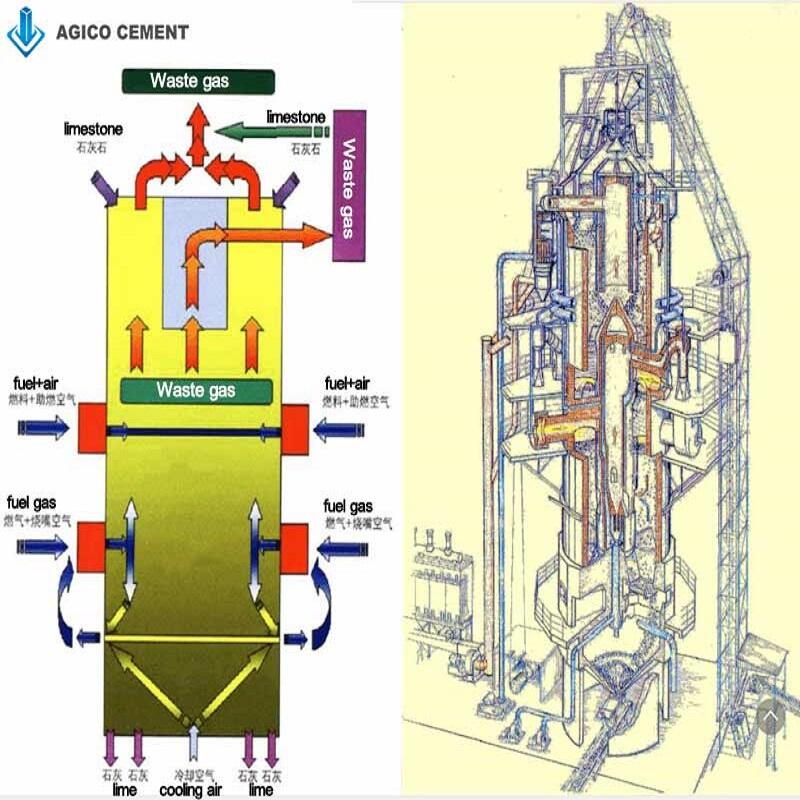

The 500-ton annular shaft lime kiln is an exemplary model with a systematic process flow. It features upper and lower layers of burners, each layer with six evenly distributed burners spaced 3.9 meters apart at a 30-degree difference. The lower burners define the countercurrent and downstream calcination zones. The combustion chambers include arch bridges made of refractory materials, ensuring even distribution of hot gas throughout the material bed.

Comprising inner and outer cylinders, the annular sleeve active lime kiln forms an annular space for limestone calcination. Divided into preheating, countercurrent calcination, cocurrent calcination, and cooling zones, the kiln maintains optimal conditions for uniform limestone calcination. The upper inner sleeve, suspended on top, and the lower inner sleeve, positioned in the middle, are constructed of boiler steel plates with refractory materials for efficient cooling.

This design ensures even pressure, airflow, and temperature distribution, enhancing limestone calcination uniformity, and product quality, and reducing unit consumption. The kiln's three zones are defined: a 9-meter preheating zone (90-140°C to 850-900°C), an 11-meter calcining zone (850-900°C to 900-950°C), and a 7-meter cooling zone (900-950°C to 80-130°C).

In the preheating zone, waste heat is minimized through an upper inner sleeve and heat exchanger design, utilizing low-calorific gas or high-CaCO3 limestone. The calcination zone hosts 70-80% of the process, primarily in the countercurrent calcination zone. The downstream calcination zone handles the remaining 20-30%. The cooling zone efficiently exchanges heat with cold air, reducing lime temperature before discharge (80-130°C). This innovative annular shaft lime kiln not only optimizes production efficiency but also exhibits adaptability to various raw materials, distinguishing it from traditional lime kilns.

Competitive Advantage:

lThe annular shaft lime kiln has changed the original positive pressure operation mode of the shaft kiln, and now it has changed to negative pressure operation without flue gas and dust overflow, which is more conducive to environmental protection requirements.

lThe upper and lower layers are arranged with the staggered distribution of multiple combustion chambers, and each combustion chamber is connected to the inner cylinder through an arch bridge made of refractory masonry so that the high-temperature smoke generated by combustion is evenly distributed so that the stone can be heated evenly.

lThe calcination quality and activity of lime can be improved by the combination of calcination and calcination through the preheating zone, upper countercurrent calcination zone, middle countercurrent calcination zone, and lower co-flow calcination zone.

lUse the inner cylinder to preheat the primary combustion air, and recycle part of the flue gas through the heat exchanger to preheat and reduce energy consumption.

lA high degree of automation, simple operation, and convenient adjustment.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ