Crusher and vibrating screens are significant in aggregates processing and mining industries. They help in the classification of materials based on the size of the particle. Evidently, this not only creates more something from nothing in that it increases the efficacy and longevity of one of the most complicated systems in the workplace. However, it also increases output thus, more profits or creation certainties. They have been designed to handle the relentless circumstances of continuous action, which only means they will always measure up to what you have in mind. Therefore why are crusher vibrating screens this vital to a crushing plant? Every Cement International Engineering crushing plant would be rendered useless without the screening process. Vibrating screens ensure links between the different crushers and other machines in the mining plant. Though, it elevates output from the moment it ensures all material particle sizes are uniform across all materials in every crushing phase. Moreover, where sizing graduations are needed, for instance, a greater quantity of material, different screening and scalping solutions are utilized. Selective sieving action has significantly slashed recirculation loads, which are constrained by limited pre-screening achieved through screening machines in pre-screening plants allowing crushers to operate at unrestricted capacities oblivious of screened products while throwing the oversize overboard. As such, the total throughput goes up leading to higher output and more profits.

Every crushing plant owes its very existence to the magic screening process. The crusher vibrating screens are a vital link between the different crushers and other equipment in mining facilities. This vibrating screen for stone crusher process increases production output by delivering an even gradation of material notwithstanding the crushing stage and achieves a reduction in specimen sizes using varying screening and scalping solutions. This selective sieving action has significantly reduced the recirculation loads which were limited by pre-screening through screening units enabling crushers to operate at their maximum capacity while being unaffected or overwhelmed with unprocessed oversized materials. As a result, the total put goes up to lead towards elevated efficiency and profitability.

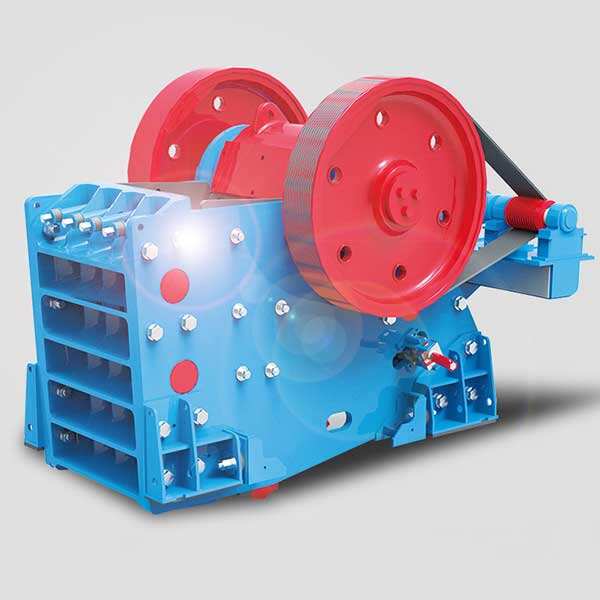

The screens are made of wear-resistant materials with well considered principles that can cope with the unique challenges often found in mining and quarrying applications. The high frequency vibrations, when the correct tilt angles are used on the Cement International Engineering screen only moves material downwards across it instead of redistributing retained liquids or solids at different depths in collection pans thus increasing screening efficiency. Adjustable amplitude, and stroke settings make the stone jaw crusher machine versatile in the wide ranging materials properties ensuring longevity. To support this performance and prolong the service life such level of equipment requires regular maintenance implementing, amongst others timely worn parts replacement as well thorough lubrication.

Choosing just the right vibrating screen for your specific application is essential. The choice of screen is based on factors like, abrasiveness and needed capacity, moisture content in the product to be processed as well as the particle size distribution. The modular designs and a range of mesh sizes give users flexibility to customize the screen depending on their own individual challenges. Further, the integration of smart technologies such as vibration analysis systems also can help to monitor performance and detect potential problems before they have a chance to develop will ensure that stone jaw crusher is able to be seamlessly integrated into any crushing circuit.

Sustainability has become a major theme in the industry as it is across many industries, including aggregates. Eco-crusher vibrating screens are designed to minimize dusting and noise pollution, along with reducing energy use - contributing green technology for a better tomorrow. Encapsulated screens and noise-reducing linings are just a few of the innovations aimed at improving performance while addressing environmental worries. It may also be a rare combination with the renewable energy sources or a more efficient drive system, which used in all stages of jaw stone crusher machine is just another way to do it and at least one important proxy can help in gaining them goals set up move crusher operations on level for global sustainability.

AGICO owns Crusher vibrating screen technical staff, with focus on EPC turnkey projects, covering design, manufacture installation, as well as debugging and maintenance, other services. AGICO provides comprehensive pre-sales, after-sales after-sales services, offering full technical support to meet requirements customers.

company has focused on engineering design and program design, special equipment supply Installation and commissioning employee training, oven service, furnace start-up, production reaching of the energy-saving and sustainable lime shaft kiln. company has constructed activated kilns various volumes which include 150m3, 170m3, 250m3,350m3, etc. They were successfully opened and showed remarkable results! gas-burning kiln was designed using technology that was been developed in the coke Crusher vibrating screenshaft. Design contracts concluded with many companies.

more than 20 years, are committed to development, research Crusher vibrating screeninstallation of the lime-kiln. is full-automatic with the lowest cost investment. lime kiln has an extended life span we are able to be relied upon due to excellent service high-quality lime mill.

a long time, AGICO has had a Crusher vibrating screentechnical team, mature production technology, rich production experience, forming complete set shaft kiln production technology management systems, making energy-saving and environmental-protective lime shaft kiln technology perfect. technology boasts the benefits low capital investment, a high levels of automation, top quality of the product, low power consumption, long lifespan of furnace as well as environmental protection. has been extensively used in metallurgy, non-ferrous metals, chemicals, building materials, as well as industries, including deep processing industries and other industries.