Vibrating screens are one of the most important bucket elevator machines used in mining and mineral processing industries. The power of the vibrating motor then enters into several screens with different sizes, Sifting by its round movement

When you buy a circular vibrating screen machine, the first point is that it must meet your own use requirements. Important factors that should be considered when comparing are the capacity, unit size and number of screens on the machine as well as build quality, screen types used and general design. With this information in mind, there are crucial factors that have to be considered to achieve the highest screening performance and productivity from your machine.

If you are considering about how to remove impurities in the sand and improve your efficiency, Then we recommend that a high performance circular vibrating screen is installed. They are designed to increase the output, reduce downtime and improve accuracy for screening results. Moreover, premium-quality circular vibrating screen bucket conveyor machines provide an array of benefits including high efficiency, better accuracy and reduced maintenance costs. Their easy-to-use designs allow even minimally trained personnel to run them providing another layer of cost savings in the screening process.

Some important points to be noted before you purchase the perfect circular vibrating screen machine for your industrial applications this is also true that have diverse screening requirements different businesses can take working screenshots. There are many different types and sizes of vibrating screen machines available (each with their own unique features, advantages, perfections,) so doing comparisons on other too must asking industry experts is important to pick this right machine for your needs.

These new generation circular vibrating screen machines also the most advanced screening precision, and we can increase productivity with our best cost in your industry. These highly efficient machines are provided with very unique designs of screen which allows to meet the most challenging screening demands. In addition, businesses have the opportunity to personalize these mechanisms according to their particular requirements and interests boosting operational efficiency and screening ability.

To conclude, the circular vibrating screen machine is an efficient high-quality workhorse that has helped in-time screening across different industry operations. A lot of businesses tend to achieve the highest screening efficiency overall productivity in case they invest one first-grade circular vibrating screen machine. These machines can change businesses' screening processes for the better once you craft them with quality machined parts construction, so that they are ready to move forward and help your business grow.

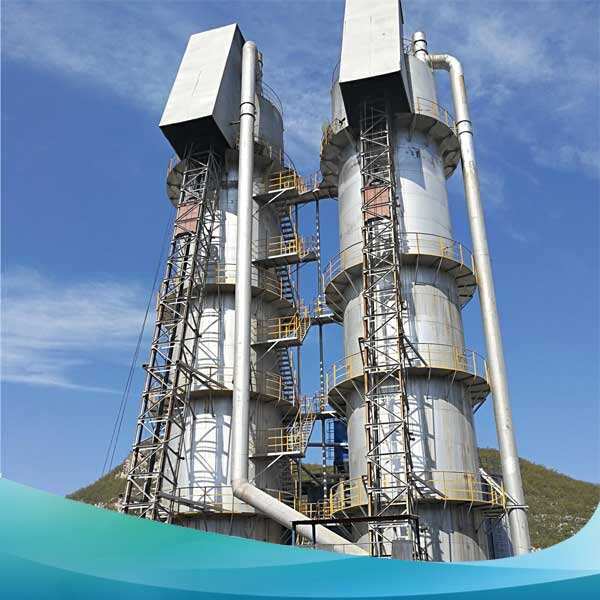

over 20 years, we've been devoted development, research, design, production, installation of lime kiln which is a green kiln and fully-automatic. is also low investments, a low circular vibrating screen machineenergy and more. can be trusted for our top-quality flawless service, as well as long-lasting lime kiln.

For long time, AGICO has had a professional technical team, mature production technology, rich production experience, forming complete set shaft kiln production technology management systems, making energy-saving environmental-protective lime shaft kiln technology perfect. technology characterized by that are low-cost investment, a superior degree of automation, high product quality, low energy consumption, long life of the furnace, circular vibrating screen machineprotection. is widely used in metallurgy, nonferrous chemical, metals, construction materials, as well as other industries, deep processing industries as well as other industries.

company has mostly undertaken engineering design and program design, special equipment provision well as installation and commissioning personnel training, oven services starting up furnaces, as well as production reaching of energy efficient sustainable lime shaft kiln. have built successively lime circular vibrating screen machinekilns that were activated with volumes 150m3,170m3 200m3, 250m3, 350m3, 500m3, etc. These were then successfully opened the effect was astonishing! Utilizing latest technology the coke lime shaft kiln the gas-burning lime shaft is kiln has been designed, and agreements design have been concluded with numerous companies.

AGICO a professional technical team, which circular vibrating screen machinein EPC turnkey projects, which include the design, manufacture installation, as well as debugging maintenance, other services. AGICO offers full range pre-sales as well as -sales service addition after-sales technical assistance.