Vápenková pec je zvláštny druh strojového zariadenia, ktoré je rozhodujúce pre výrobu cementu. Dnes sa v tomto článku s názvom vápenka dozvieme o peci, čo to je a ako funguje, jej históriu a prečo je taká užitočná. Pozrieme sa aj na to, kde sa už dnes používa v rôznych odvetviach. Cement International Engineering je renomovaná spoločnosť, ktorá vyrába tieto špecializované pece používané pri výrobe cementu.

Vápenec je druh skaly, ktorá Roztok pre rastliny vápna stroje používané na výrobu betónu. Je to obrovská pec a zvyčajne vyzerá ako veľká rúra z tehál alebo kovu. Vápenec sa vo vnútri tejto trubice zahrieva pri extrémne vysokých teplotách - takých vysokých, že sa stáva tekutým (materiál nazývaný nehasené vápno). Po zmiešaní nehaseného vápna s vodou vzniká látka nazývaná hydroxid vápenatý, ktorý je nevyhnutný pri výrobe cementu. Toto je kritická látka, pretože pomáha držať materiály pohromade a vytvárať silné štruktúry.

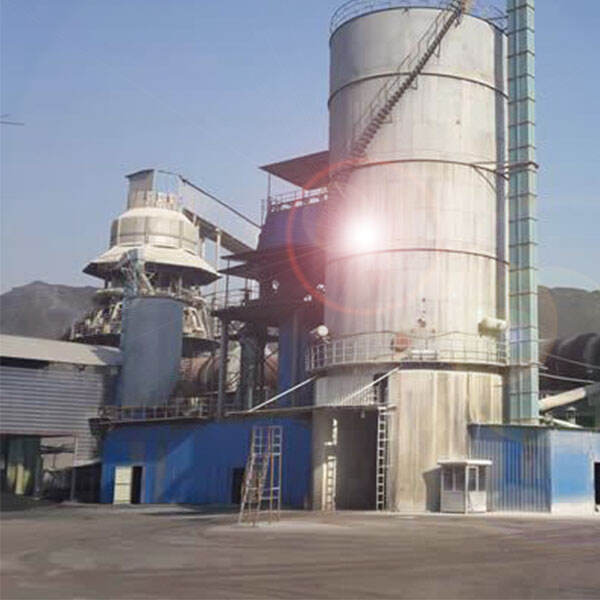

Vápenková pec Cement International Engineering priamo ohrieva vápenec na extrémne vysoké teploty. Proces začína, keď sa vápenec naplní do hornej časti pece. Aby sa dosiahli tieto teploty, vápenec sa varí asi dve hodiny pri 1000-1100 °C s uhlím alebo olejom. Vápenec sa zahrieva na vysoké teploty a pri zahrievaní podlieha niekoľkým chemickým zmenám, ktoré z neho robia nehasené vápno. Po tejto transformácii sa produkt nehaseného vápna vypustí z pece ventilom na dne a potom sa ochladí na použitie v rôznych iných aplikáciách.

Vzácne, ale svojou povahou fascinujúce vápenné pece majú za sebou dlhú históriu. Prvá mažiar a paličky boli použité v starovekom Grécku pred stovkami rokov na výrobu malty, ktorá sa používala v stavebníctve. Táto technológia Cement International Engineering čoskoro prešla do starovekého Ríma, kde jednou z hlavných výrobných potrieb bola konštrukcia betónu pre cesty, akvadukty a mnoho ďalších kritických systémov. V roku 1800 Rotačná vápenka boli prijaté a pomohli postaviť základy toho, čo dnes poznáme ako náš stavebný priemysel.

Používanie vápennej pece má mnoho výhod. Pôsobí ako efektívny spôsob výroby ton nehaseného vápna v jednom ťahacom cykle, a preto je ekonomický. To umožňuje spoločnostiam byť nákladovo efektívne a zároveň držať krok so svojimi výrobnými potrebami. Po druhé, pece na výrobu vápna sú energeticky efektívne vďaka použitiu palív, ako je spaľovanie uhlia, oleja alebo plynu, ktoré sa používajú na poskytovanie tepla. Tretia hodnota 100 nemusí byť spoľahlivá, pretože celý proces na týchto strojoch môžete jednoducho sledovať a kontrolovať. Nakoniec, nehasené vápno vyrobené z týchto pecí je prvotriednej kvality a môže byť použité v stavebníctve, poľnohospodárstve a ťažobnom priemysle.

Dnes sme videli vápenné pece a ich využitie presahovalo rámec výroby cementu. Teraz Vertikálna vápenná pec sa používajú aj na cukor, papier a širokú škálu chemikálií. Environmentálne aspekty: Zvyšuje sa povedomie o výhodách pre životné prostredie a vyššia priorita pri využívaní vápenných pecí pri stanovovaní emisií skleníkových plynov z tovární. Na tento účel sa namiesto bežných fosílnych palív, ako je uhlie a ropa, používa biomasa (rastlinný materiál).

Spoločnosť AGICO má už dlhú dobu profesionálny technický tím, vyspelú výrobnú technológiu, bohaté výrobné skúsenosti, tvorí kompletný súbor systémov riadenia technológie výroby šachtových pecí, vďaka čomu je technológia šachtových pecí na výrobu vápna, ktorá šetrí energiu a chráni životné prostredie, dokonalá. technológia je Vápenka peceby sú nízkonákladové investície, vysoká úroveň automatizácie, špičková kvalita produktov, minimálna spotreba energie, dlhá životnosť pece, ochrana životného prostredia. je široko používaný v hutníckom sektore, ako aj neželezné kovy chemikálie stavebné materiály, rôzne priemyselné odvetvia, ako aj hĺbkové spracovateľské odvetvia.

Vzhľadom k tomu, viac ako 20 rokov, sa zaviazali k rozvoju výskumu, dizajnu výrobnej inštalácie vápenky-pec. je plne automatická s výdajmi vápenky. vápenka má dlhú životnosť, vďaka vynikajúcemu servisu nám môže dôverovať kvalitný vápenný mlyn.

Spoločnosť sa zaoberala najmä návrhom programu inžinierskeho projektovania, poskytnutím špeciálneho vybavenia, ako aj zaškolením zamestnancov na inštaláciu a uvedenie do prevádzky, servisom pecí na spúšťanie pecí, ako aj dobudovaním vápenky pre energeticky úspornú, ekologickú šachtovú pec. Spoločnosť postavila aktivované pece rôznych objemov, ktoré zahŕňajú 150 m3, 170 m3, 250 m3,350, 3 mXNUMX atď. Úspešne otvorené vytvorili ohromujúci efekt! S využitím modernej technológie šachtovej pece na koksové vápno bola navrhnutá šachtová pec na spaľovanie vápna a boli podpísané zmluvy s rôznymi spoločnosťami.

AGICO, vysoko kvalifikovaný tím pre pec na výrobu vápna, sa špecializuje na projekty EPC na kľúč, vrátane výroby, dizajnu a inštalácie. AGICO ponúka komplexný predpredajný, predajný a popredajný servisný systém, ktorý poskytuje technickú podporu potrebnú na uspokojenie potrieb zákazníkov.