सजावटी सीमेंटेशन भट्टियाँ यहाँ हैं। ये कच्चे माल को सीमेंट (अंतिम उत्पाद) में बदलने के लिए काम करते हैं। सीमेंट इंटरनेशनल इंजीनियरिंग एक ऐसी कंपनी है जो पूरी गति से आगे की सोच रखती है, उसे तेज़ और बेहतर बनाने की ज़रूरत है। इसलिए फ़ाइव्स ने नए विचारों और नवाचारों के लिए फिर से सहयोग किया है जो इस बढ़ती हुई हरी दुनिया में पहले से कहीं ज़्यादा महत्वपूर्ण हैं। यह सुनिश्चित करना कि भट्ठी ज़्यादा मेहनत करे! दुनिया भर के कई देशों को भट्टियों की ज़रूरत होगी, जो सीमेंट के उत्पादन के तरीके को बेहतर बनाने के लिए तकनीक का एक महत्वपूर्ण हिस्सा है।

भट्ठा- एक बड़ा, गर्मी प्रतिरोधी ओवन जिसका उपयोग कुम्हार अपने बर्तनों को बहुत उच्च तापमान पर पकाने के लिए करते हैं। सीमेंट बनाने के लिए पिसाने से पहले कच्चे माल को 2,500 डिग्री फारेनहाइट से अधिक तापमान पर भट्ठे में भूनकर क्लिंकर बनाया जाता है। क्लिंकर एक ठोस पदार्थ है जो पोर्टलैंड सीमेंट के निर्माण में एक मध्यवर्ती उत्पाद के रूप में उत्पन्न होता है और अब तक वह और एक अंतिम पीसने का चरण बाकी है, जहां इसे अन्य सामग्रियों के साथ पीसा जाता है, जो कि पिछले टर्नओवर में भी भगवान जानता है कि हम कैसे अपराजित रहे; मैं सोच रहा था कि आपने इतना खराब क्यों खेला (आमतौर पर प्रीमियरशिप सीजन); जैसे ज्वालामुखी की राख को आसानी से काम पर जाने के लिए सबसे कठिन यात्रा में मिला दिया जा रहा है जिसका सामना किसी भी टीम ने फीफा लेख के संबंध में जेसुल्डो भगवान द्वारा किया है।

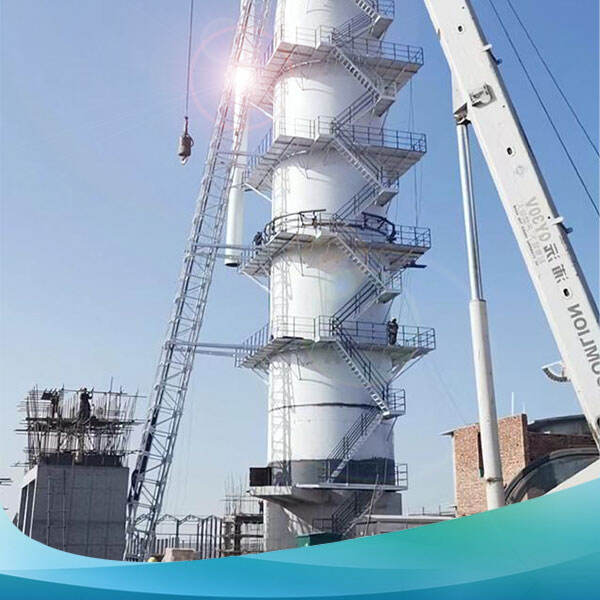

सीमेंट बनाने के लिए दिलों से बने भट्टे। यह काम कच्चे माल को बहुत अधिक तापमान (1000 के दशक में) पर गरम करके और फिर परमाणुओं के अन्य बदलाव करके किया जाता है। ऐसे उच्च तापमान पर, कच्चे माल में रासायनिक परिवर्तन होते हैं जिसके परिणामस्वरूप क्लिंकर बनता है। इसलिए ऐसा कोई सीमेंट नहीं है जिसे क्लिंकर के बिना बनाया जा सके। सीमेंट इंटरनेशनल इंजीनियरिंग छोटा रोटरी भट्ठाइसलिए, इसमें बहुत सारे आवश्यक हिस्से होते हैं जो भट्ठे को काम करने में सक्षम बनाते हैं। इन हिस्सों में भट्ठे के खोल में एक आग रोक अस्तर (एक विशेष प्रकार की गर्मी प्रतिरोधी बाहरी परत) शामिल है, जो एक प्रकार का चिकना आवरण होता है जो इसे उच्च तापमान से बचाता है, और पहिए ताकि यह हमेशा गतिशील रहे।

भट्ठी की दक्षता महत्वपूर्ण है। फिर सीमेंट इंटरनेशनल इंजीनियरिंग सीमेंट इंटरनेशनल इंजीनियरिंग को और अधिक विकसित करने के लिए कड़ी मेहनत और तेजी से काम कर रही है विद्युत रोटरी भट्ठीवे अपने काम में दक्षता बढ़ाने के लिए युक्तियों पर ध्यान केंद्रित करते हैं। जो एक छोटे से तरीके से लागतों को बचाता है और पर्यावरण की रक्षा के लिए भी एक कारण है, उनमें से एक ऊर्जा बचत भट्टियों का उपयोग करना है। उत्पादन लागत को कम करने का एक और तरीका बेहतर गुणवत्ता वाले कच्चे माल का उपयोग करना है जिसके साथ सीमेंट बनाने के लिए बहुत कम ऊर्जा का उपयोग किया गया है। इससे सीमेंट आर्थिक रूप से कम खर्चीला हो जाता है और उत्पादन प्रक्रिया और भी अधिक कार्बन-मुक्त हो जाती है।

भट्ठा उद्योग में, नए नवाचारों की आवश्यकता है और यह एक स्वच्छ दुनिया के लिए भी महत्वपूर्ण है। सीमेंट इंटरनेशनल इंजीनियरिंग हमेशा अपनी प्रौद्योगिकी स्थिरता में लगातार सुधार करके सबसे सुरक्षित और स्वच्छ सीमेंट उद्योग के लिए प्रयासरत रही है। वे भट्टों में वैकल्पिक ईंधन डालकर ऐसा करते हैं। ये वैकल्पिक ईंधन अपशिष्ट पदार्थ हो सकते हैं, जैसे कि इस्तेमाल किए गए टायर और प्लास्टिक। पारंपरिक अनुभव के साथ अल्ट्रा फिनटेक उद्योग को बचाने के लिए अपशिष्ट को कम करने और ऊर्जा के लिए इस्तेमाल किए जाने वाले कम पारंपरिक जीवाश्म ईंधन को त्यागने के लिए - माँ पृथ्वी के लिए अच्छा है।

इस तरह, भट्टियों ने आज तक सीमेंट के वैश्विक उत्पादन को बदलने में मदद की है। अधिकांश देश सीमेंट उद्योग के लिए भट्टियों का उपयोग करते हैं। वे सबसे अधिक सीमेंट का उपयोग करते हैं, और उनके पास सीमेंट इंटरनेशनल इंजीनियरिंग है अप्रत्यक्ष प्रज्वलित रोटरी भट्ठी - बेनब्रिज एट अल द्वारा 2010 में किए गए अध्ययन (सर्वेक्षण) से पता चलता है कि भारत, अमेरिका और ब्रिटेन द्वारा सीमेंट बनाने के लिए भट्ठों का उपयोग किया जाता है, जिसकी आवश्यकता भारत जैसे स्थानों पर निर्माण और बुनियादी ढांचे की जरूरतों के लिए अधिक मात्रा में कंक्रीट बनाने के प्रयासों में होती है।

AGICO एक पेशेवर तकनीकी टीम है, जो सीमेंट उद्योग में EPC टर्नकी परियोजनाओं में भट्ठी का काम करती है, जिसमें डिजाइन, निर्माण स्थापना, साथ ही डिबगिंग रखरखाव, अन्य सेवाएं शामिल हैं। AGICO बिक्री से पहले और बिक्री के बाद तकनीकी सहायता के अलावा पूरी रेंज प्रदान करता है।

पिछले 20 वर्षों से, सीमेंट उद्योग में भट्ठे के विकास, अनुसंधान, उत्पादन स्थापना चूना भट्टों के लिए प्रतिबद्ध हैं, जो पर्यावरण संरक्षण और पूरी तरह से स्वचालित हैं। यह कम खर्च, कम ऊर्जा खपत आदि भी करता है। हम अपनी शीर्ष गुणवत्ता और निर्दोष सेवा, और लंबे समय तक चलने वाले चूना भट्टे के लिए भरोसेमंद हैं।

लंबे समय से, AGICO के पास पेशेवर तकनीकी टीम, सीमेंट उद्योग में परिपक्व उत्पादन भट्ठा, समृद्ध उत्पादन अनुभव, शाफ्ट भट्ठा उत्पादन प्रौद्योगिकी प्रबंधन प्रणालियों का एक पूरा सेट बनाना, ऊर्जा-बचत और पर्यावरण-सुरक्षात्मक चूना शाफ्ट भट्ठा प्रौद्योगिकी को परिपूर्ण बनाना है। प्रौद्योगिकी में कम निवेश, उच्च गुणवत्ता वाले स्वचालन, बेहतर उत्पाद गुणवत्ता, कम ऊर्जा खपत, भट्ठी की लंबी सेवा जीवन और पर्यावरण संरक्षण के लाभ हैं। धातु विज्ञान उद्योग में और निर्माण सामग्री, विभिन्न उद्योगों और गहरे प्रसंस्करण उद्योगों में अलौह धातु रसायनों में भी व्यापक रूप से उपयोग किया जाता है।

कंपनी ने डिजाइन इंजीनियरिंग डिजाइन, विशेष उपकरण वितरण, सीमेंट उद्योग में भट्ठी की स्थापना, कर्मियों के प्रशिक्षण, ओवन सेवाओं, भट्ठी स्टार्ट-अप और ऊर्जा कुशल पर्यावरण के अनुकूल चूना शाफ्ट भट्ठी तक पहुंचने पर ध्यान केंद्रित किया है। हमने 150m3,170, 3m200 3m250, 3m350 3m500 3mXNUMX आदि की मात्रा के साथ क्रमिक रूप से सक्रिय चूना शाफ्ट भट्टियों का निर्माण किया है। फिर इन्हें सफलतापूर्वक खोला गया और प्रभाव प्रभावशाली था! गैस-जलने वाली भट्ठी कोक लाइम शाफ्ट में परिपक्व हुई तकनीक का उपयोग करके बनाई गई थी। कई कंपनियों के साथ डिजाइन अनुबंध संपन्न हुए।