Tez shof kundozalari bu jihatdan sanoat ishlab chiqarish dunyosidagi eng yaxshi misollaridan biri hisoblanadi, asosan hamma qurilish materiallari uchun muhim tizimlar sifatida xizmat qiladi va to'qirq non ushlanadigan kamaydigan reaktivlikka ega bo'lgan foydali mahsulotga o'tkazadi - tezshof. Bu amal oxirgi qadamonning sohasida muvaffaqiyatli ravishda amalga oshirilgan va hozirda turli sanoatlar, qurilishdan ekologik boshqarimgacha, uchun juda muhim qolgan. Tezshof, kalsium oksid (CaO) uchun umumiy nom, bunday foydali bo'lib, uning olingan va qayta olingan tarixi onlab ming yillik davrda davom etgan. Shuningdek, shu buyicha kimyoviy formulalash talab qilinadi. Bunday kimyoviy tarkiblar, tezshof bilan solishtirilsa, tarixiy yuz yoki ming yillardan beri ochiq bolmagan qismlar mavjud. Tezshofni nimadir? Ushbu maqolada biz tezshof kundozasi operatsiyalariga to'xtiramiz - ularning foydalanishi, ishlab chiqarish effektivligini yaxshilash uchun taktilar va turli sanoatlardagi amaliy mashg'ulotlar haqida. Kalk yurakli furnasi shofnonni qanday ishlab chiqarish mumkin? Bu maqolada biz tez lime kiln operatsiyalari haqida keng tarqatamiz - ularning foydasi, ishlab chiqarish effektivligini yaxshilash uchun usullar va ekologik parametrlar, shuningdek turli sanoatlardagi amaliy misollar.

Vikipediadan: **shaft kilns** ning rotary tube dan foydalanishiga nisbatan quyidagi imkoniyatlari bor. Quick lime tuzumlari bir necha qulayliklarni taqdim etadi, bu esa klassik kattik dizaynidan yuqori. Birinchidan, ular LTE-yangilash orqali yanajon ishlashini yaxshilab beradi va shuningdek mashxur ekonomiyasini oshiradi. Asosiy pechlar Bu jarayon boshqa materiallar bilan reaksiyaga kirishi kerak bo'lgan mahsulotlar uchun muhim hisoblanadi va shu holatda, nazoratlangan jarayon orqali amalga oshirilgan material qo'shimcha qo'yilmaydi (shuningdek, pollutsiya kamaytiriladi). Bundan tashqari, muassasiy fast limestone furnaces avtomobil to'plamining talablari va rivojlantirilayotgan talablariga moslashish uchun tez ravishda o'zgartirilgan. Shuningdek, ko'p o'zgaruvchan shtat tirikligi ortib borayotgan bo'lsa-da, sanoat talablari bo'yicha tez va effektiv ravishda o'zgarishi mumkin bo'lgan investitsiya kelajak uchun isbotlangan bo'ladi.

Sensorni, PLC (Dasturlanadigan Mantik Maydonlari) va SCADA (Nazorat va Ma'lumot Olish Sistemasidan foydalanib rivojlantirilgan tez kalkon kilnlari, bu modern kilnlar har doimiy temperatur nazorati uchun ta'minlay oladi shuningdek shaft kilnini material oqimi energiya saqlashga yordam beradi. Kalsatsiya operatsiyasi davomida optimal eslituvni saqlashga qarama-qarshi ishlash orqali, ushbu tizimlar atrofda bo'lgan xato sonini kamaytirish va ko'proq chiqim imkoniyatini ta'minlashga imkon beradi, hamda konstant mahsulot sifatini ta'minlaydi. Faqat muvaffaqiyatsizliklar yuzaga kelishi oldidan operatorlarni ogohlantirishdan tashqari, ushbu tizimlar muvaffaqiyatsizliklar oldindan oldin yuzaga kelishini oldini olish uchun prognostik texnologik holatni ta'minlaydi.

VA, bugungi kunda ekologik yurakliq faqat kecha tomonga qarash emas va keyingi maxsus qo'shimchalar sifatida ham emas, balki uning boshqarilish printsipi sifatida ishlaydi. Modern talablar bilan urinib chiqadigan, ekologik texnologiyani ishlatuvchi va past emissiyali smart tez shof kundozalari. Masalan, ba'zi kundozalar ekskurs ushiligini foydalanadi va bu energiyani boshqa maqsadlar uchun foydalanish uchun atrof-muhitdan foydalanish tizimlaridan foydalanadi, bu esa karbon izini kamaytiradi. Shuningdek, sofistikatsiya qilingan suzma filtratsiya tizimlari ham ko'plab ekologik qoidalar bo'yicha sutqoq va emissiyalar bo'yicha moslikni ta'minlaydi. Shof umumiy echkiy yondashuvda alternativ yonimchilar, masalan, biomas va xato gazlari kabi buyumlarni ishlatish ham shu muhimligini belgilaydi.

Sur limuzining ishlab chiqarish prosessi, yuqoraga shikillangan izvestkoviy tozalarni kilyoda surx zamon bilan 900⁰C dan yuqori olinib, butunlaydi. U holda eng tezroq havaga kiradi va qonli joylar orqali qandaydir soatda yoyiladi. bunday baland haroratlarda karbonat mineralar ajratiladi va karbondioxid (CO2) gazini chiqaradi (CaO + CO3 = CaCo3\/SDT\/). Kilyoning aylantirish harakati haroratning teng ravishda tarqalishi va gaz almashuvini ta'minlashga yordam beradi. Sur limuzining kaltsinatsiyasi yakunlangandan so'ng, u yaqin suvga tushirilib hidratlangan lim uzatiladi yoki to'g'ridan-to'g'ri ishlatish uchun olinadi. Ishlash jarayonida, mahsulotning sifati va xavfsizlik saqlanishi uchun haroratni boshqarish va turlicha vaqtda e'tiborga olinishi kerak.

20 yildan ko'p vaqt o'tdi, biz ekologik va to'liq avtomatik kalsiyum kilnini rivojlantirish, tadbiq qilish, dizayn qilish, ishlab chiqarish bilan shug'ullanib kelibmiz. Shuningdek, kichik investitsiyalar va past energiya sarflashiga ega. Bizning eng yaxshi keyfiyatli xizmatimiz va davom etuvchi kalsiyum kilnimizga ishonib bo'ladi.

AGICO tez ishlab chiqarishgi suda qurilishi bo'yicha mutaxassis EPC bandimizda turibdi, bu yerda ishlab chiqarish, dizayn o'rnatish, tozalash xizmatlari, boshqa xizmatlar ta'minlangan. Sotuvdan oldingi va sotuvdan keyingi xizmat tizimi taqdim etadi, kerakli texnik yordamni taqdim etadi va mijozlarning talablarini qanoatlantiradi.

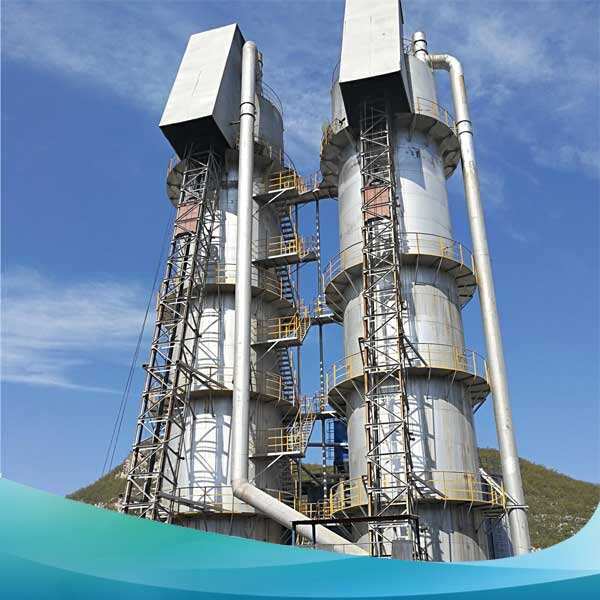

Uzoq muddatlik AGICO-da mutaxassis texnik jamoasi, sovg'a ishlab chiqarish texnologiyasi va bog'liq ishlab chiqarish tajribasi mavjud, shuning uchun to'liq komponentli suda ishlab chiqarish texnologiyasi va boshqarish tizimlari yaratildi, energiya saqlash va ekologik himoya qilishgi suda texnologiyasini mustaqil qiladi. bunda pastki tezgi suda, avtomatlashtirish darajasi baland, mahsulot sifati yaxshi, elektr energiyasi sarfi kam, tandirning ishlash vaqti uzun va ekologik himoyalangan. metallurgiya va rangli kimyo savdo, metallar, qurilish materiallari va boshqa savdoda keng tarqalgan.

kompniya dastur dizayni, inzhener dizayni, maxsus texnika ta'minoti va hamda ishchiqlarni o'rnatish va ishga tushirish uchun tarbiyalash, tandoq xizmatlari, kuryon ishga tushirishi, energiya saqlash va yashil qizilg'ich shaht kilni ishlashiga yetib borishga yo'naltirilgan. Kompaniya har xil hajmdagi faollar qizilg'ich kilni qurib chiqqan, masalan 150m3, 170m3, 250m3, 350m3 va boshqalar. Kilnlar muvaffaqiyatli ravishda ochilgan va remarkable effektda! Koksli qizilg'ich shaht kilning eng yaxshi texnologiyasidan foydalanib, gazorli qizilg'ich shaht furnusi rivojlantirilgan va ko'plab kompaniyalar bilan dizayn uchun shartnomalar imzolanadi.