De Top 10 Kalkovensfabrikanten om te kennen!

Voordelen van het Gebruik van Kalkovens

Kalkovens zijn een essentieel onderdeel dat wordt gebruikt in verschillende industrieën zoals bouw, staal, cement en mijnbouw. Deze ovens worden gebruikt om kalksteensool te produceren, wat essentieel is voor vele toepassingen. Kalkovens hebben Verticale Kalkovens vele voordelen, waaronder het volgende:

- Kalkovens kunnen grote hoeveelheden kalksteensool produceren tegen lage kosten.

- De Cement International Engineering zijn zeer veelzijdig en kunnen worden gebruikt in verschillende industrieën.

- Ze hebben een minimale impact op het milieu van anderen.

- Ze bieden uitstekende materiaaloverdrachtcontrole, wat een hoge kwaliteit constante uitkomst waarborgt.

- Kalkovens hebben lage energiekosten en vereisen weinig onderhoud.

Innovatieve kenmerken van kalkovens

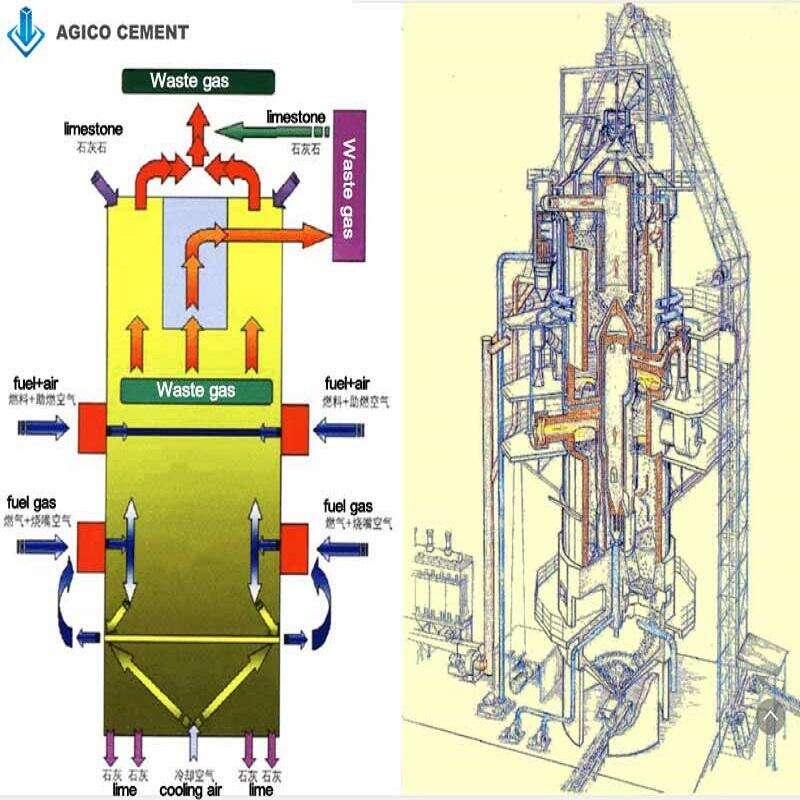

Innovatie is essentieel voor technologische vooruitgang, en kalkovens blijven niet achter. Wij hebben over de jaren heen verbeteringen gezien in hun functies. Verschillende fabrikanten introduceren nieuwe innovatieve kenmerken die hun kalkovens efficiënter, productiever en veiliger maken. Bijvoorbeeld, het gebruik van geavanceerde automatiseringstechnologie controleert en reguleert het kalkovenproces, waardoor de prestaties van de oven toeneemen, de kwaliteit van het eindproduct verbetert en de operationele efficiëntie verhoogt.

Veiligheid van kalkovens

Veiligheid is een factor die belangrijk wordt beschouwd bij het gebruik van kalkovens. Het productieproces van kalk is gevaarlijk en kan ernstige ongelukken veroorzaken als het niet zorgvuldig wordt behandeld. De top 10 kalkovenfabrikanten stellen veiligheid centraal in hun ovenontwerpen en hebben daarom verschillende veiligheidsmaatregelen in hun kalkovens geïmplementeerd om ervoor te zorgen dat ze veilig opereren. Functies die veiligheid waarborgen omvatten interlocksystemen, Annulaire schachtovens persoonlijk beschermend uitrusting, conveyors veiligheidsschakelaars, en noodgevallenresponsystemen.

Hoe kalkovens te gebruiken

Het gebruik van een kalkoven kan intimiderend lijken, vooral voor nieuwe gebruikers. Toch is het een eenvoudig proces dat weinig tot geen kennis of ervaring vereist. Kalkovens werken door kalksteen (die in de oven wordt gestopt) om te zetten in kalk. Deze chemische reactie plaats op zeer hoge temperaturen. Zodra de kalk geproduceerd is, wordt deze vervoerd uit de oven met behulp van conveyors. Kalkovens worden doorgaans bediend door professionele medewerkers die zijn getraind in veiligheid en operationele procedures.

Kwaliteit en Service van Kalkovens

Kwaliteit en klantenservice zijn essentiële factoren om in aanmerking te nemen bij het selecteren van de beste kalkovenfabrikant. De top 10 kalkovens prioriteren de behoeften en tevredenheid van hun klanten. De Dubbele As Kalkovens bieden uitstekende klantenservice om hun klanten te helpen bij het oplossen van eventuele problemen die ze kunnen tegenkomen tijdens de bediening van hun kalkovens. De fabrikanten zorgen er ook voor dat hun kalkovens van de hoogste kwaliteit zijn, wat zorgt voor hoge productiviteit en lage onderhoudskosten.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ