迅速に進む製造プロセスにおいて、クイックライムプラントは不可欠です。これらは、鋼鉄、セメント、紙、プラスチックなどを含むさまざまな最終用途産業で高品質の石灰を製造するために使用されます。これからお読みいただく記事では、最先端のクイックライムプラントに投資することで、工業生産がどのように劇的に増加し、他の利点としてすべてのプロセスがより滑らかに進行して製造が改善されることを説明します。

ここでは、産業生産性を向上させ、ビジネスを新しいレベルに成長させるのに役立つトップ5のクイックライムプラントについて議論します:

第一産業: 過去の時代から約60年が経過し、私たちは高品質の酸化カルシウムと優れたエネルギー効率を持つクイックライム工場で繁栄しています。環境負荷を軽減するためには、85%から99%の純度の石灰製品を生産する単一シャフト垂直キルンを使用できます。この低圧運転は少ない排出ガスを意味し、小規模から中規模の産業向けに生産プロセスを最も効果的に最適化することができます。

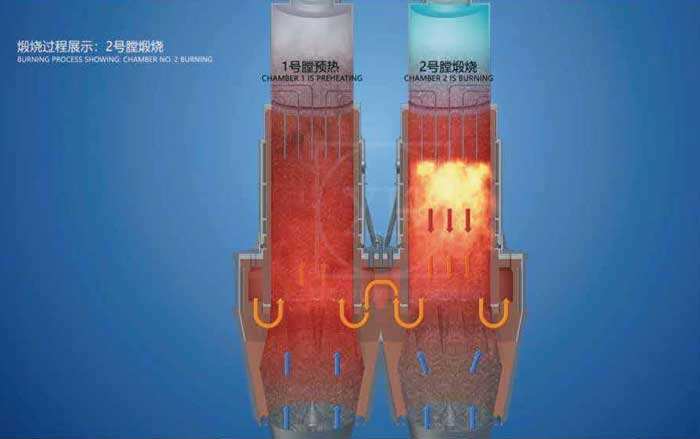

第二の産業: そのロール式粉砕機は、信頼性が高く、出力が大きく、メンテナンスコストが低いクイックライム工場で構成されています。この粉砕機の興味深い特徴の一つは、一部の石灰が燃焼前に分離器で既に粉砕され、乾燥されており、その後、環状シャフトキルンを通じて処理されてクイックライムになります。その結果、残留水分が少なく、質感が明確で、さまざまな工業用途に適した高品質のクイックライムが得られます。

第三の産業の工場は小規模から中規模であり、垂直シャフトキルン(VSK)を使用しています。シュリージャインフラソリューションのVSK石灰プラントの強みは、この単一の設備セットです。これらの施設は低い反響温度を達成でき、さまざまな種類の燃料を使用してより効率的に石灰を生産できます。さらに、VSK石灰プラントは水和石灰、ドロマイト石灰石、および酸化マグネシウムなどの他の製品も生産可能です。

第四の産業: 安定した解決策を持つ石灰焼成プラントで、生産性とクイックライムの品質を向上させるためにアップグレードされています。これはDx5を通じて回転キルンを使用する現代技術を採用しており、低排出量とエネルギー消費が特徴です。他の燃料と組み合わせて使用でき、このプラントは一日に1200トンの石灰を生産することができます。

ライム水和プラントでは、水と化学反応することにより消石灰が作られます。このプラントは年間6万トンの生産能力があり、糖類精製、皮革加工、水処理に必要な消石灰を苛性ソーダと競合するコストで提供します。日量400トンまでの消石灰を生産でき、このプラントは生産性向上を目指す中小規模の工業企業にとって理想的です。

高速ライムプラントは、あなたの工業的な生産量だけでなく、顧客の要求に応えるために必要な製造プロセスの改善も促進するために最適に設計されています。小規模から中堅、大手企業まで、この最先端の高速ライムプラントへの投資は、効率的な石灰生産による成長を促進する解決策となります。

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ