Introduction

Les fours à chaux sont essentiels lorsqu'il s'agit de transformer la pierre calcaire en un produit utile. L'ingénierie internationale du ciment aide à réduire la taille du matériau, à convertir le brut en une poudre qui peut être utilisée dans diverses applications. En particulier, les fours à chaux verticaux gagnent en popularité en raison de leur efficacité et de leur rentabilité. Nous examinerons les cinq meilleurs fabricants de fours à chaux verticaux et ce qui les distingue.

Avantages des fours à chaux verticaux

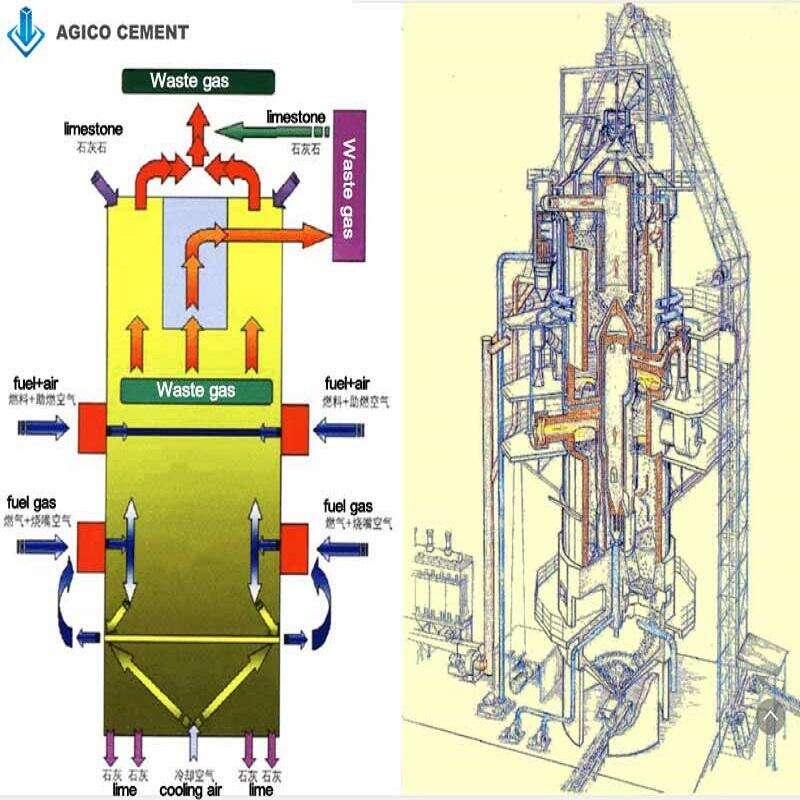

L'un des principaux avantages des fours à chaux verticaux est leur efficacité. Ils sont conçus pour utiliser moins de carburant et produire plus de chaux par unité de carburant que les fours horizontaux. Cela est rendu possible par la conception du four vertical, qui permet au calcaire de se déplacer dans le four dans une direction verticale, offrant ainsi un transfert de chaleur plus efficace.

Un autre avantage des fours à chaux verticaux est leur polyvalence. Ils peuvent être utilisés pour traiter différents types de Fours à Chaux Verticaux calcaire, y compris ceux riches en calcium, dolomites et magnésiens. Cela les rend utiles dans de nombreuses industries, notamment l'acier, le papier et la construction.

Innovation dans les fours à chaux verticaux

Les meilleurs fabricants de fours à chaux verticaux innoveront continuellement pour améliorer leurs produits. Un domaine d'innovation réside dans l'utilisation de technologies pour surveiller et contrôler les fours. Les fabricants intègrent des capteurs et des systèmes de surveillance permettant une supervision en temps réel des conditions du four. Cela aide à optimiser les performances du four et à améliorer la qualité du produit.

Un autre domaine d'innovation concerne la conception même du four. Les fabricants expérimentent avec Fours à chaux différents matériaux et conceptions pour créer des fours plus efficaces et plus sûrs à utiliser.

Sécurité et utilisation des fours à chaux verticaux

La sécurité est une priorité pour les principaux fabricants de fours à chaux verticaux. Ils sont conçus avec des fonctionnalités de sécurité telles que des systèmes d'arrêt automatique et des boutons d'arrêt d'urgence. Les fabricants fournissent également une formation en matière de sécurité à leurs clients sur la manière de faire fonctionner les fours en toute sécurité.

Il est essentiel de s'assurer que le four est correctement alimenté et entretenu lorsqu'il s'agit de l'utilisation de fours à chaux verticaux. Le Fours à chaux annulaires le calcaire doit être chargé dans le four avec soin et à la bonne vitesse pour garantir un traitement efficace. Il est également crucial de surveiller régulièrement les conditions du four pour s'assurer que la chaux produite est de la qualité souhaitée.

Service et qualité

Les meilleurs fabricants de fours à chaux verticaux offrent un excellent service à leurs clients. Ils proposent un support après-vente, y compris des services de maintenance et de réparation, pour s'assurer que les fours de leurs clients fonctionnent efficacement. Ils fournissent également une formation à leurs clients sur la manière d'utiliser et d'entretenir correctement les fours.

La qualité est un autre domaine où les meilleurs fabricants de fours à chaux verticaux se distinguent. Ils utilisent des matériaux de haute qualité et appliquent des mesures strictes pour s'assurer que leurs produits répondent aux normes les plus élevées. Cela garantit que leurs clients reçoivent un produit fiable et cohérent avec leurs besoins.

Applications des fours à chaux verticaux

Les fours à chaux verticaux ont de nombreuses applications, y compris dans la production de chaux et de chaux vive hydratée. La chaux vive est utilisée dans de nombreuses industries, notamment l'acier, le papier et la chimie, tandis que la chaux hydratée est utilisée en agriculture, dans la construction et le traitement de l'eau.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ