An annular shaft kiln is a kind of continuous feeding and discharging calcining furnace that has found application in the primary cement production industry for approximately hundred years owing to characteristics such as high output with progressive (or without) fuel replaced along the process,high utilization rate throughout operation, low energy consumption,simple engineering,easily constructed and easily maintained. These are the special kilns that employed in cement manufacturing process. So here in this article, we go all over the deep to prove Top 5 reasons why Annular Shaft Kiln is touted as a Cement manufacturing future.

Specific pulse System for Annular Shaft Kiln- Energy Efficiency

Energy- One of the prime factors for having edge over product manufacture Energy which plays an important role in Cement and energy is a crucial part to be considered as far as its impact on Carbon sequestration is concerned, Modular design Annular Shaft Kiln. could minimise power consumption. This design of kiln can save a ton on energy. This enables precise temperature control and therefore reduces radiation and convection heat losses. Additionally, the setup is said to reduce fuel use by assisting in mass and heat transfer.

Besides, this can achieve a preheating zone by the kiln residual heat makes input raw materials become up to be desired temperatures. Hence, this preheating process actually consumes less energy to heat the material demanded and hence requires lower fuel addition which also reduces costs. Annular Shaft Kiln -> Energy And Cost Saving and Generates Low Carbon_CART_advantages

Benefits of Annular Shaft Kiln in Cement Production

Cement Production Benefits of Annular Shaft Kiln The kiln itself is a model unique in the world, because it is designed to give great versatility in gas flow, temperature and residence time control required for the production of high-quality cement on an industrial scale. It also assist in higher production per unit volume size useful for small scale to large cement producers/ plant operator or even big plants moving a step further to improve their process and become highly competitive too.

Moreover, the Annular Shaft Kiln start-up faster and with lower operating costs than traditional rotary kilns. With its easy to handle refractories and sections which can be built into shapes when necessary, it reduces downtimes and enable low maintenance costs. This is actually a very good choice in regard to saving space, time, and future expense as low-maintenance Annular Shaft Kiln will take up little room for something you care about.

All is because of Why Annular Shaft Kiln the futures

The unique design of the Annular Shaft Kiln presents a range of features that is likely to make it an alternative for future cement making. Which allow small cement plants benefit from low operating and maintenance costs. The higher production capacity of the kiln results in improved efficiency and also reduced cost of cement.

Moreover, the efficient layout of 'ANNULAR SHAFT KILN' offers significant fossil fuel cost savings resulting in fewer Co2 emissions throughout occurrence having created; Raymond Mills Features Its efficient performance in the manufacturing process has been proven by various methods as you can see on the advantages section above;Environment:"The Annular Shaft Kilnis zero-emission clean burn techonlogy and it save pollution completely." since clearly without Jason(Parceljason. It is poised to be particularly appealing for companies seeking to decrease their carbon emissions or comply with government environmental sustainability incentives. And ultimately, the capability to grind other materials make DSS an excellent precursor in demands of cement sector.

Flexibility with an Annular Shaft Kiln for Cement Production

The Annular Shaft Kiln is widely recognised to provide the most versatile production of cement (Ordinary Portland Cement OPC 100%,Portland PozollanaCement PPC & Portland SlagCEment PSC). The kiln can also be configured with different fuel options (fossil, solid or liquid fuels) and sizes to meet various local site conditions as well as the flexibility in regard to available fuel.

Besides even the kiln may be built to manufacture various cement grades plants can crush on different segments. All Cement Companies in Need of a Variety of FunctionsThe various functions provided by the Annular Shaft Kiln allow it to be ideal for all cement companies, that want many choices if they have concrete production.

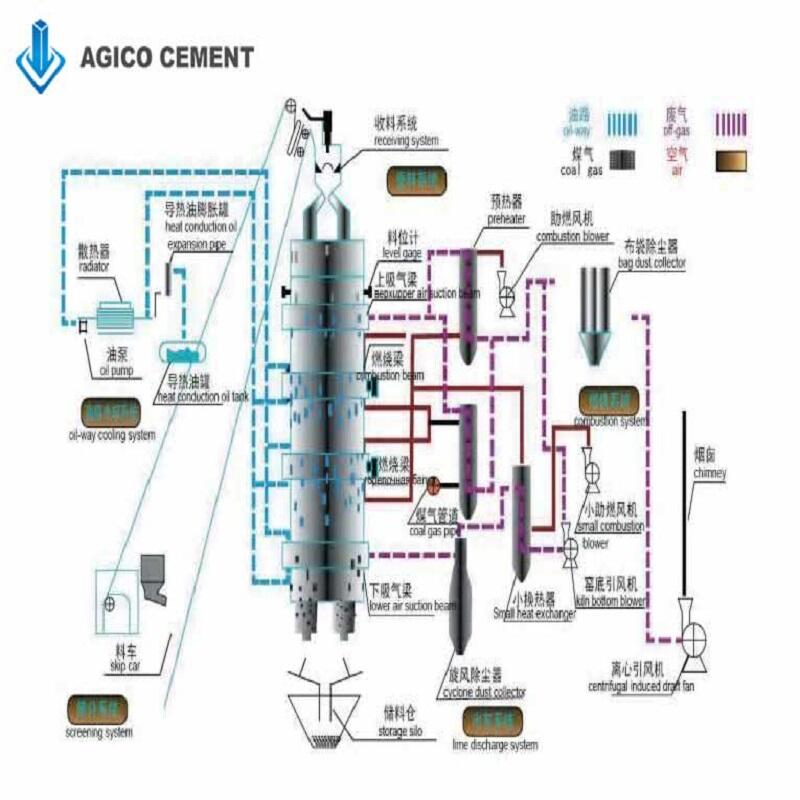

Working of Annular Shaft Kiln in Cement Plant

This Annular Shaft Kiln has the characteristic of exploiting and producing that cannot be completely eliminated. An inclined kiln at an angle of % 37.5 on his own axis will prevent the most from heat loss and make it much simpler to move hot material into cold inlet (Calcining Zone) where raw materials are pre-heated up close production temperature for optimum effectiveness.highest performance). Then, they get transported to the burning zone where chemical reactions take place making cement.

This shaft is a circular chamber that sits above the combustion zone and funnels off all of the ashes from burning process. The gases must be raised to a cool temperature, so they remove these too and use the energy taken from this to preheat an incoming material before allowing it into the kiln. At the top of these columns, gases are burned and then excreted out from the bottom with fewer pollutants being emitted into our environment.

Thus from the traditional rotary kiln and Annular Shaft Kiln in upgrading furnace about energy efficiency as this approximately 40% of reduction is cost-plus environmental benefits. This fantastic investment tool that is able to accommodate such a variety of tipical operations as well will hopefully allow cement companies all tail gabrielino the opportunity they need to take full advantage and yet remain green. The Annular Shaft Kiln is a single kilns design in accordance to proven refractory plate manufacturing techniques. A world of less carbon-intensive and more sustainable technologies beckons - as epitomized by inventions like the Annular Shaft Kiln for cement manufacture.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ