Vertical lime kilns is the type or kind of commercial built equipment to build quality lime. Lime is an important homebuilding which is understood the different uses. The Cement International Engineering procedure of producing lime is referred to as calcination, which involves heating the limestone rock to release carbon dioxide and convert it into quicklime. Vertical lime kilns need gain popularity amongst construction companies with regards to their numerous benefits. We will explore the top 10 benefits of vertical lime kilns.

Advantages of Vertical Lime Kilns

Vertical lime kilns have numerous advantages compared to many other types of lime kilns. For example, they will have higher thermal efficiency meaning eat less energy compared to other kilns. They likewise have the top-notch finish for their constant temperature distribution. Also, these are typically compact in dimensions, meaning they occupy less space and require less initial money.

Innovation

Vertical lime kilns are incredibly revolutionary, with various companies introducing more recent technology constantly. This can help to make sure that customers hook up to newer, more efficient equipment fulfill their needs. A number of the Vertical Lime Kilns recent milestones vertical lime kiln technology include better combustion technology, engineered firebrick, and insulation materials, and others.

Use of Vertical Lime Kilns

Vertical lime kilns are an easy task to use, making them perfect for construction companies that need quick turnaround times. These kilns might be run by a tiny group and their compact size means are easy to move from webpages to site. Furthermore, as a result of their compact size could be built on-site and personalized to fulfill particular criteria.

How to use Vertical Lime Kilns

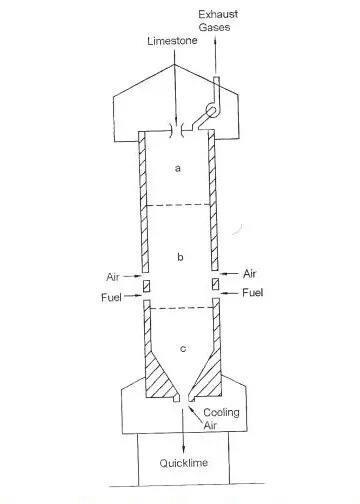

Utilizing a vertical lime kilns is a simple procedure with just minimal training required. The procedure involves loading limestone the chamber, whenever it is heated at high conditions of approximately 1000-1100°C. The heated limestone then released from the kiln, conveyed towards the cooler section, and then packed prepared for use. The strategy is continuous, making certain there is constantly the constant provide of lime.

Safety

Safety is the important part of commercial equipment. Vertical lime kilns have a few safety features that produce them safe for use. For instance, they will have a high-temperature limit that shuts down the equipment in case of overheating. Also, a Lime Kilns smoke is have by them escape system that prevents the accumulation of harmful gasses in the kiln.

Service

Vertical lime kilns need minimal maintenance, creating them perfect for use in remote areas. Nevertheless, they nevertheless need regular repair checks to create certain performance is optimal. Fortunately, most manufacturers offering after-sale solutions, including installation, upkeep, and repair solutions. This ensures that customers have the ongoing best service possible.

Quality

Vertical lime kilns produce high-quality utilized lime for different needs, like construction, agriculture, and mining. The consistent warmth to the kiln ensures that in conclusion item is of superior quality. Furthermore, vertical kilns use less energy, creating them eco-friendly and sustainable.

Application

Vertical lime kilns are utilized in several applications, including glucose refining, steel, Double Shaft Lime Kilns and nonferrous metals manufacturing. Also, they have been used in the creation of glass, concrete, and paper, and others. Also, as a result of the compact size can be utilized in remote areas to generate quality lime for regional communities.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

LO

LO

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ